Pioneering Precision and Efficiency in Global Manufacturing

Learn how NextasTech is driving the future of CNC machining and automation with our advanced quick-change workholding solutions.

Our Journey: 15 Years of Innovation

Founded in March 2009, NextasTech has been building industrial workholding solutions from our base in Zhuhai, Guangdong, China (No. 19, Jinkang Road, Hongqi Town, Jinwan District). We design, develop, and manufacture high-precision quick-change clamping systems and automation-ready fixtures. Our integrated approach combines R&D, production, and global sales, supported by a 43,313 m² production base.

Today, our team includes 366 employees, with a strong engineering backbone including 250 R&D engineers. We support OEM/ODM programs—from sample-based customization to full design-to-production—helping customers shorten changeover time, improve repeatability, and scale into automated machining.

Verified Company Facts

For buyers who need extra confidence, the key company details below are aligned with our verified public profile on Made-in-China (TÜV Rheinland).

Established

2009

Founded on 2009-03-06

Business Type

Manufacturer / Factory

+ Trading Company

Employees

366

Engineering-driven team

Plant Area

43,313 m²

Zhuhai, Guangdong

Member Status

Diamond Member

Since 2024 (Made‑in‑China)

Buyer Protection

Secured Trading

Service available on platform

Factory Tour

360° Virtual Tour

Available on verified profile

Reviews & Activity

5.0/5

US$10,000+ (6‑month transactions)

Quality & Compliance

- Management system: ISO 45001:2018

- Finished products: 100% inspection (visual + function)

- Raw material traceability: Yes

Trade & Delivery

- MOQ: 1 set

- Incoterms: FOB, EXW

- Lead time: within 15 workdays

- Nearest ports: Zhuhai / Shenzhen

R&D & Customization

- R&D engineers: 250

- OEM/ODM: available

- Customization: samples → full design

- New products launched in the last year: Yes

TÜV Rheinland Audit Reference

Audit report no.: MIC-ASI2411114 (as shown on the verified profile)

A quick tour of our facility and engineering.

Company Introduction Video

Watch how NextasTech designs and manufactures high-precision workholding solutions—quick-change fixtures, zero-point clamping systems, and automation-ready setups for CNC machining.

- Manufacturing & quality control inside our Zhuhai facility

- How our quick-change clamping systems reduce setup time

- Applications across aerospace, automotive, and precision machining

Explore our product lines: Zero-Point Clamping Systems and Self-Centering Vises.

Engineered for Excellence: Our Technology

Maximize Efficiency

Our Zero-Point System drastically reduces setup times, boosting your productivity and throughput.

Automate for the Future

Embrace Industry 4.0 with our automation-ready fixtures designed for seamless integration.

The NextasTech Advantage

NextasTech provides custom CNC workholding solutions engineered to enhance machine tool efficiency. We're committed to delivering high-quality products at competitive prices with rapid turnaround times, rivaling industry leaders like LANG and 5th Axis.

Experience the NextasTech difference—precision-engineered solutions that elevate your machining capabilities.

- Exceptional Repeatability: Typical positioning repeatability up to 0.02 mm (model-dependent) for consistent results.

- Powerful Clamping Force: Strong and stable clamping force (up to 20 kN on select models) for demanding cutting conditions.

- Internationally Accepted Connector: Universal with 52 and 96 type spigots to improve clamping efficiency.

- Quick Change Jaws: Jaws can be installed frontally or reversely. Custom soft jaws are available.

- Meticulous Design: Side clamping grooves facilitate gripping by manipulators for automation.

Explore Our Facility

Take a virtual walk through our state-of-the-art production facility. See for yourself where innovation and precision come to life.

Trusted by Industries Worldwide

From aerospace to medical devices, our precision systems provide the reliability and performance that leading global industries demand.

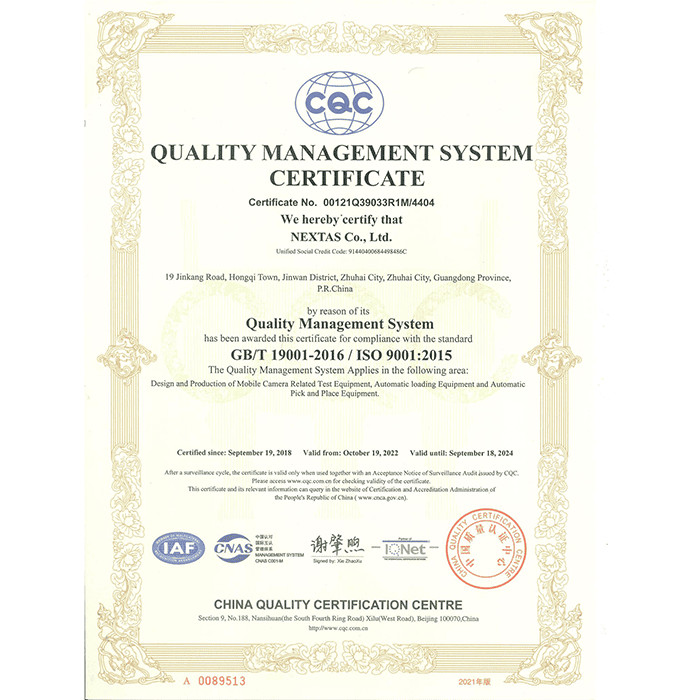

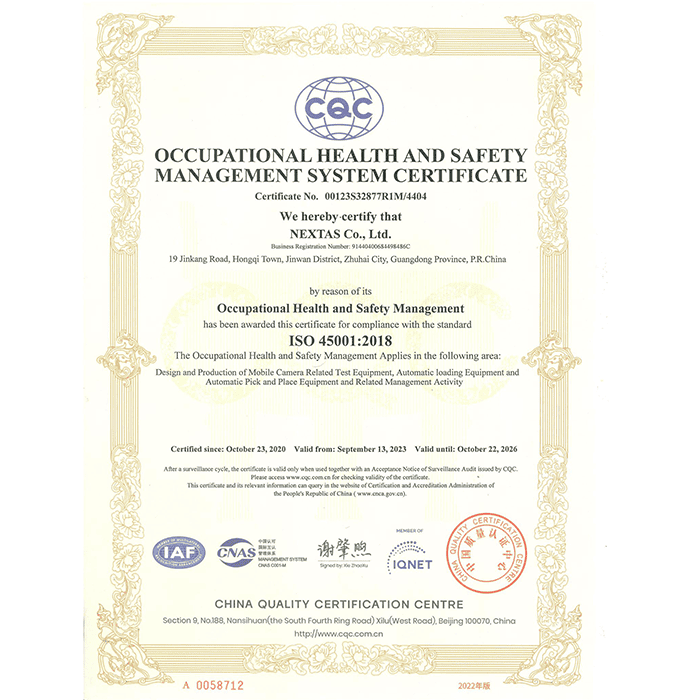

Our Commitment to Unwavering Quality

Our dedication to excellence is validated by internationally recognized certifications, reflecting our systematic approach to quality, safety, and environmental responsibility.

Quality Management

Environmental Management

Occupational Health & Safety

Certificate of Conformity

Questions Buyers Often Ask

Transparent answers help projects move faster. Below are common pre-sales questions about our capabilities, delivery, and verification.

What does NextasTech focus on in R&D?

We focus on real-world workholding upgrades—repeatability, clamping stability, fast changeovers, and automation-friendly interfaces. Our verified profile lists 250 R&D engineers, supporting continuous new product development and customization.

How do you control quality and consistency?

Our production capability is built around standardized inspection: 100% finished-product inspection (visual + function), documented inspection methods, and raw-material traceability. These items are listed on our verified company profile.

What are your minimum order quantity and typical lead time?

MOQ starts at 1 set. Typical lead time is within 15 workdays in both peak and off-season (per the verified profile). Final timing depends on model, quantity, and customization scope.

Which trade terms and payment methods do you support?

We commonly support FOB and EXW. Payment options include T/T, L/C, PayPal, Western Union, and small-amount payment (as listed on the verified profile).

Do you offer OEM/ODM and customization?

Yes—OEM/ODM is available. We support flexible customization options, from sample-based adjustments to full design customization. If you share your part drawing, machining strategy, and interface needs, we’ll recommend a stable, automation-ready setup.

Can we visit your factory in Zhuhai?

Absolutely. We welcome visits from clients and partners. You can also explore our 360° virtual tour on this page, then contact us to arrange an on-site visit.

Ready to Enhance Your Production?

Let's discuss how NextasTech can provide a tailored workholding solution to meet your specific needs. Contact our experts today.

Get in Touch