Enter your email address to request the brochure. Due to time zone differences, we’ll email it the next business morning (GMT+8, Beijing Time).

Zero-Point Clamping Systems

The Engine of Quick-Change Efficiency

The NextasTech Zero-Point Clamping System is the high-performance engine behind modern workholding. These precision-engineered modules provide the powerful clamping force and flawless repeatability needed to slash setup times from hours to seconds, forming the core of any effective quick-change or automated manufacturing strategy.

Module Core Features

- Micron-Level Repeatability: Guarantees a repeat positioning accuracy of ≤0.003mm, ensuring consistent quality.

- Fail-Safe Mechanical Locking: Clamps with powerful spring force, ensuring workpieces stay locked even if air pressure is lost.

- Immense Clamping Force: Provides exceptional rigidity to withstand the most demanding cutting operations without vibration.

- Automation-Ready: Designed for seamless integration with robotics, featuring ports for control, cleaning, and status detection.

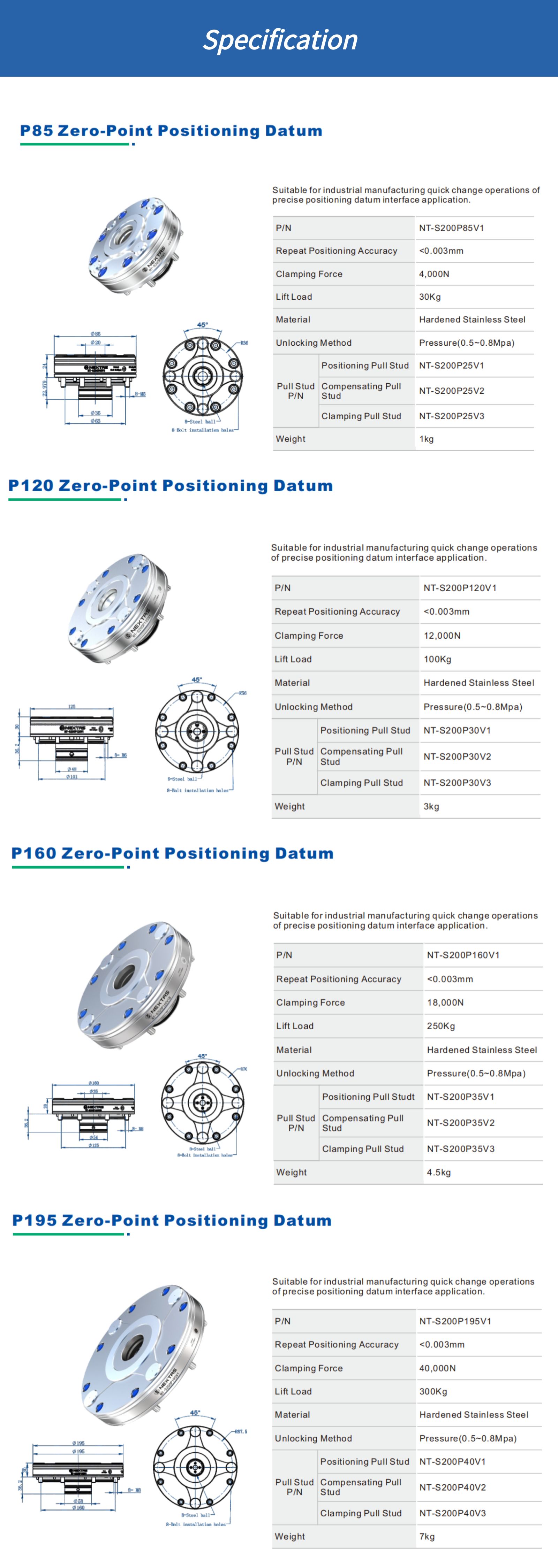

Technical Specifications

| Model | Module Diameter | Clamping Force | Lift Load | Repeatability |

|---|---|---|---|---|

| NT-S200P85V1 | 85 mm | 4 kN | 30 KG | ≤0.003 mm |

| NT-S200P120V1 | 120 mm | 12 kN | 100 KG | ≤0.003 mm |

| NT-S200P160V1 | 160 mm | 18 kN | 250 KG | ≤0.003 mm |

| NT-S200P195V1 | 195 mm | 40 kN | 300 KG | ≤0.003 mm |

Common Specifications (All Models)

- Actuation:Pneumatic Unlocking (6 bar)

- Body Material:Hardened Stainless Steel, Corrosion-Resistant

Mechanism Details

Engineered for Unfailing Performance

NextasTech Zero-Point modules are the foundation of modern manufacturing efficiency. Each module is crafted from high-grade, hardened alloy steel for maximum rigidity and service life. The ingenious internal mechanism uses pneumatic pressure (typically 6 bar) to overcome powerful springs for unlocking. When the air is removed, these springs instantly and forcefully pull in and lock the clamping stud, creating a positive, vibration-proof connection that is completely secure.

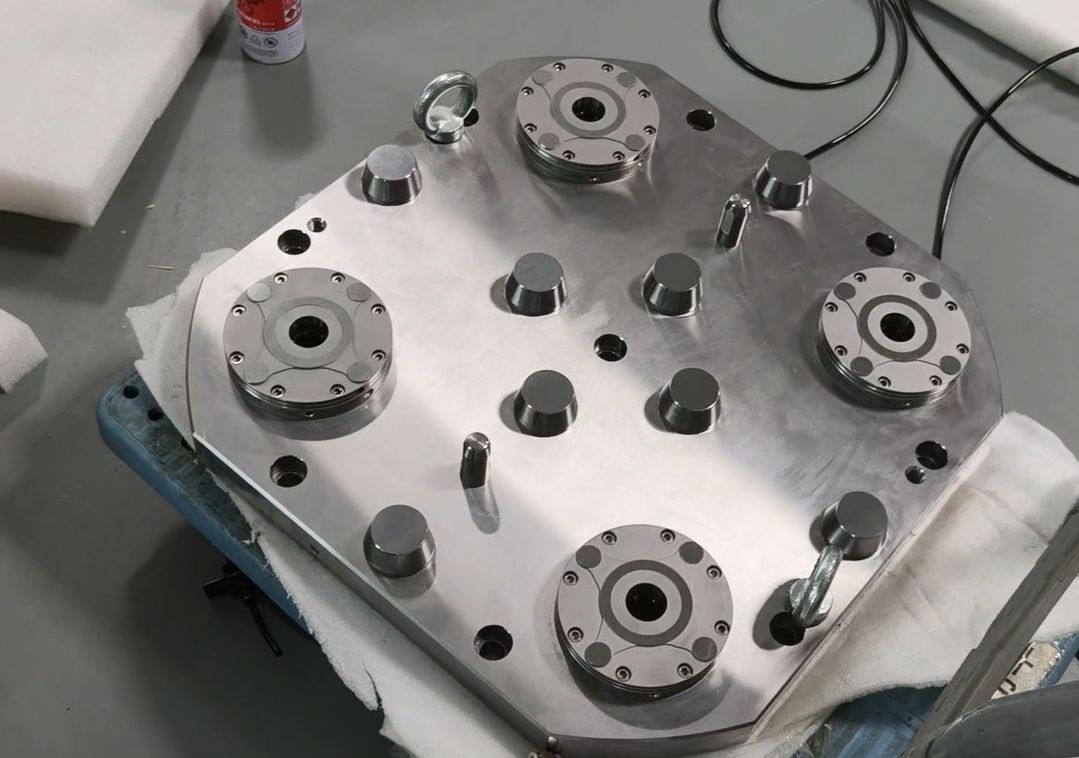

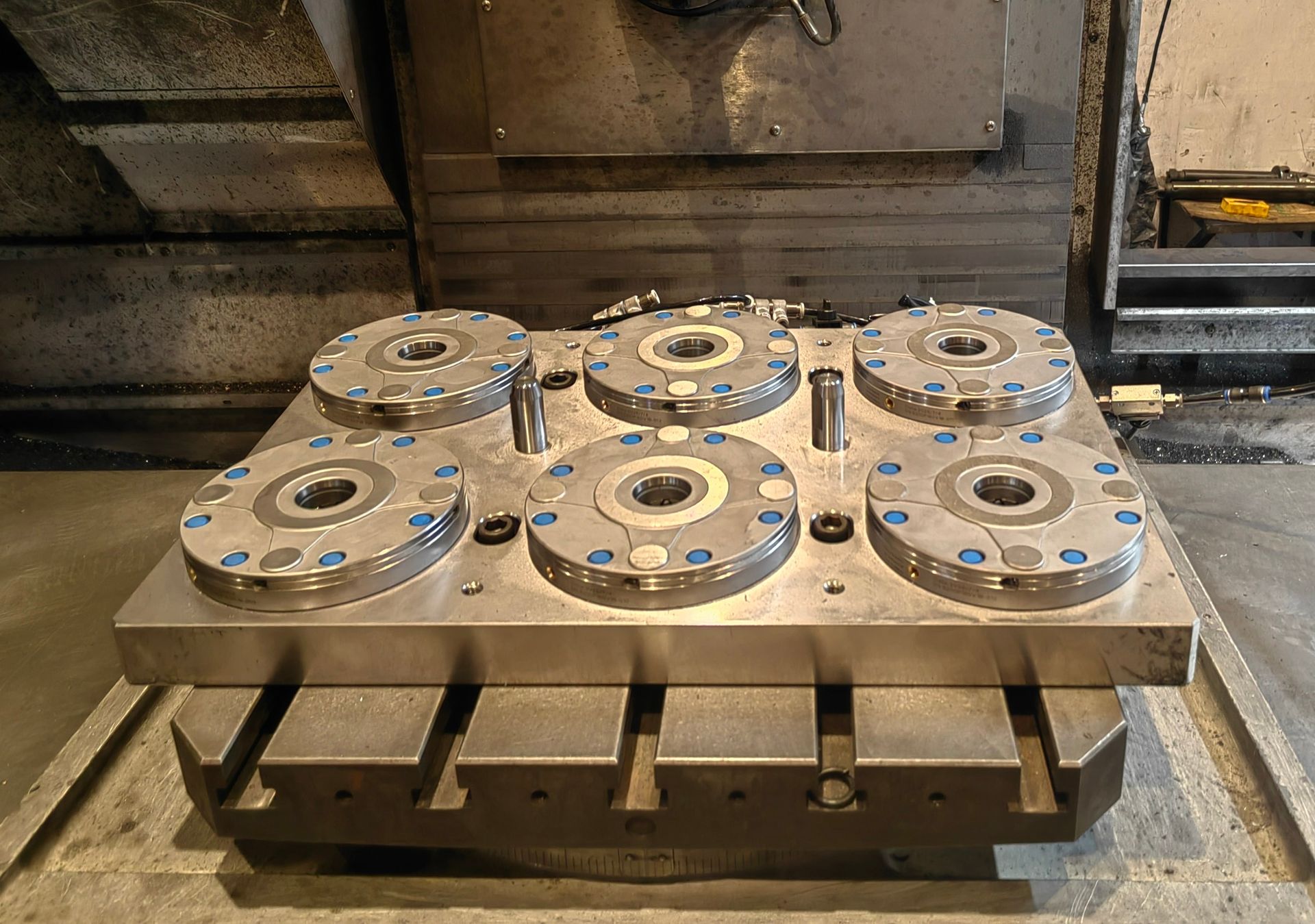

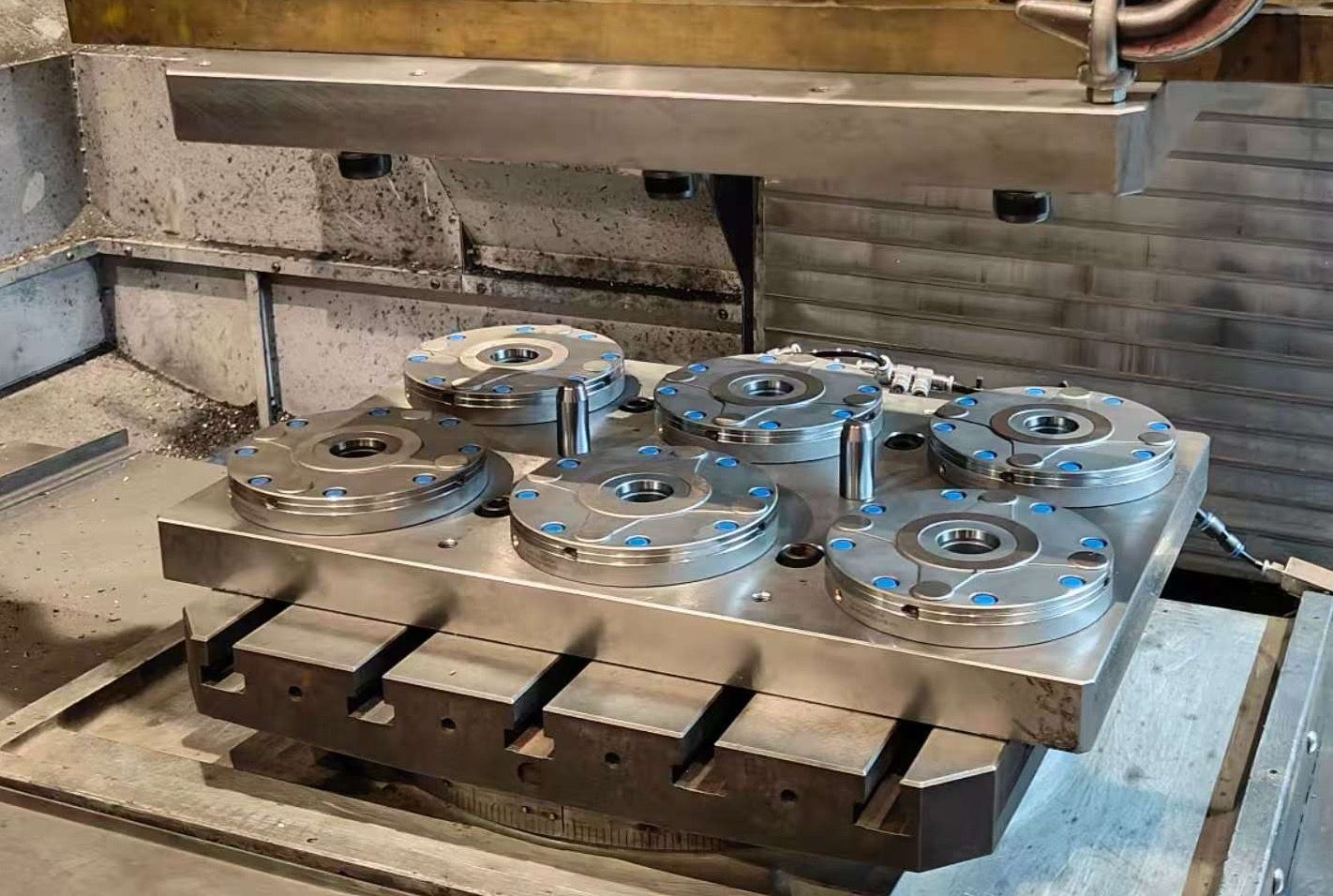

See It In Action: The Power of Instant Changeover

Watch how our Zero-Point Clamping System transforms your workflow. This demonstration showcases the incredible speed and flawless precision of our locking mechanism, allowing for pallet changes in seconds.

(7)%20(1).png?updatedAt=1754553736043)

Bottom Inlet Solution Features

- • Flexible taper fit positioning · Repeatable positioning accuracy <0.003mm.

- • High-precision ball lock self-locking structure ensures stability.

- ③⑥ Pneumatic boosting function enhances clamping force.

- ④⑦ Air-tightness testing and surface self-cleaning function.

- ⑤⑧ Pneumatic lock/unlocking and chuck lifting function.

- • Jet cleaning function inside the pull stud hole prevents debris.

- • Air-tightness testing and positioning surface self-cleaning.

Key System Functions

- Mechanical Self-Locking: Maintains 100% clamp force even if air pressure is lost.

- Clamping Force Booster: Optional turbo function increases holding force for heavy-duty jobs.

- Self-Cleaning Air Blast: Integrated channels clear debris before clamping to ensure perfect seating.

- Position Monitoring: Sensor-ready for feedback to confirm clamp/unclamp status for secure automation.

Selection & Integration Guide

How to specify a zero-point system for your machine

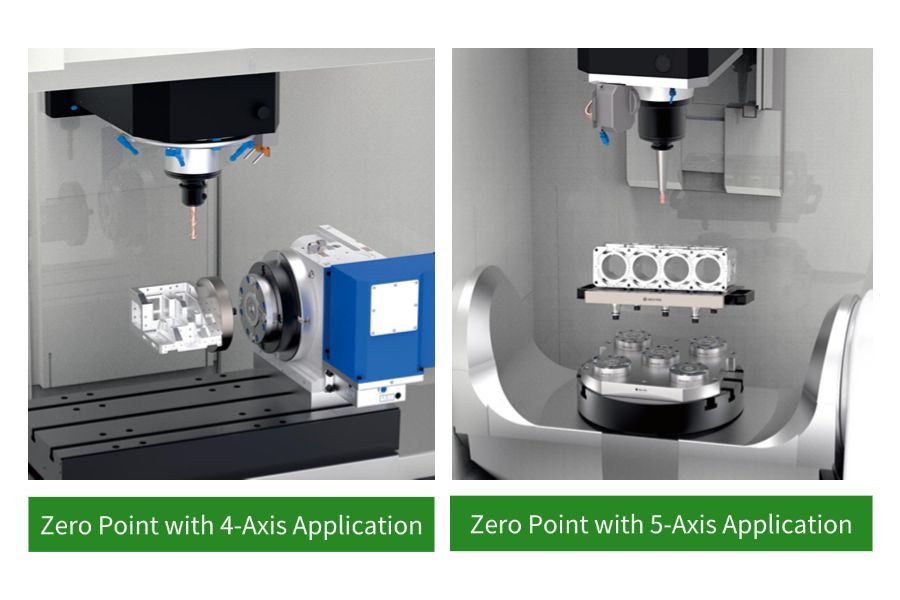

- Define your changeover goal: pallet swaps, fixture swaps, or both. This sets the receiver count and pallet strategy.

- Select receiver size: based on fixture weight, cutting load, and available footprint (85 / 120 / 160 / 195 mm options).

- Choose pull studs: standard vs. compact vs. anti-rotation, depending on clearance and datum requirements.

- Plan the sub-plate: optimize receiver spacing for tool access, chip flow, and coolant drainage.

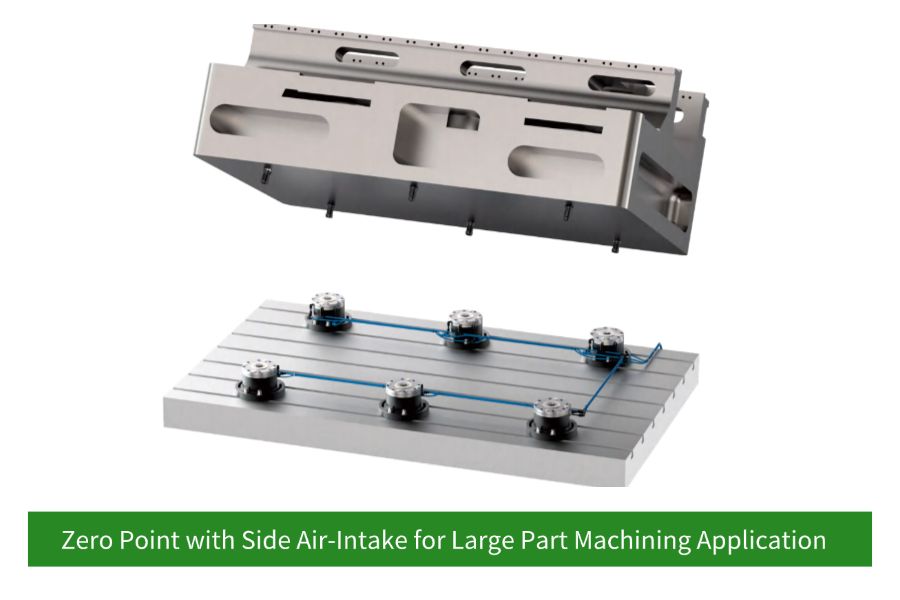

- Decide air routing: bottom inlet for clean through-table plumbing; side inlet when through-table routing isn’t possible.

- Automation readiness: add clamp/unclamp confirmation sensors for APC/robot cells and safe PLC sequencing.

Typical retrofit paths

Zero-point systems pay off fastest when you standardize one interface across multiple setups. Here are the most common upgrade routes we support.

Mount a receiver pattern on a sub-plate and add pull studs to your vises/fixtures. Great for mixed-batch work and short runs.

Use dense receiver layouts and low-profile fixtures to maximize tool access and reduce re-indicating between operations.

Add clamp confirmation signals and consistent pallets to enable safe unattended changeovers and higher spindle uptime.

Receiver sizing & layout quick guide

These guidelines help early-stage planning for a quick-change pallet / fixture interface. Final selection depends on cutting loads, moments, and machine constraints — share your setup and we’ll propose a layout.

| Use case | Typical payload | Recommended receiver | Typical receiver count | Notes |

|---|---|---|---|---|

| Compact 5-axis fixtures / vises | ≤ 30 kg | 85 mm | 3–4 |

|

| General 3-axis quick-change setups | ≤ 100 kg | 120 mm | 4 |

|

| Heavy-duty fixtures / tombstones | ≤ 250 kg | 160 mm | 4–6 |

|

| Large pallets / automation / APC | ≤ 500 kg | 195 mm | 6–8 |

|

Bottom inlet vs. side inlet routing

| Option | Best when | Plumbing notes | Automation notes |

|---|---|---|---|

| Bottom inlet | You can route air through the table/sub-plate for a clean, protected setup. |

|

|

| Side inlet | Through-table routing isn’t possible, or you need a fast retrofit on existing plates. |

|

|

Quality & Reliability You Can Audit

For zero-point workholding, repeatability isn’t just a spec — it’s the result of material control, precision grinding, and functional testing. NextasTech focuses on stable long-term performance in real chip-and-coolant environments.

Materials & wear resistance

- Hardened, corrosion-resistant steel on critical locating/locking interfaces.

- Precision-ground engagement surfaces to keep repeatability stable over cycles.

- Designed for coolant exposure with robust sealing and debris management.

Functional testing

- Air-tightness and actuation verification to ensure consistent unlock behavior.

- Self-cleaning air blast paths to protect seating accuracy in chip-heavy jobs.

- Repeatability validation guidance available for incoming inspection and FAT.

Support & documentation

- CAD/STEP files on request for fast fixture design and simulation.

- Configuration proposal with receiver spacing, porting plan, and BOM suggestions.

- Spare parts and maintenance checklist to keep uptime predictable.

Advanced Manufacturing Applications

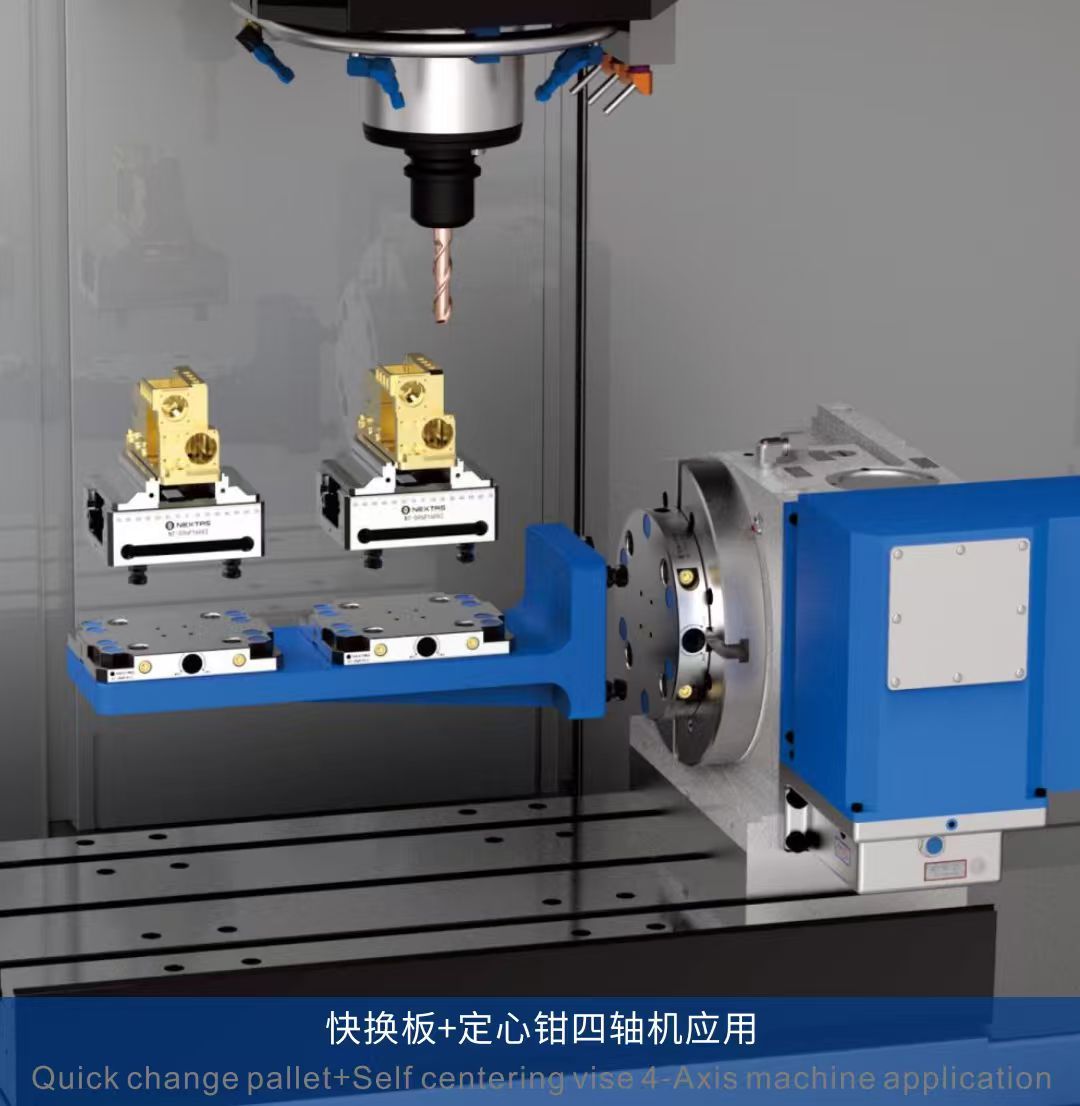

Offline Setup & Palletization

Build fixtures and mount workpieces on pallets while the machine is running, drastically increasing machine uptime.

Multi-Machine Standardization

Use the same setup across multiple machines (3-axis, 5-axis, CMMs) for ultimate flexibility and reduced fixture inventory.

Case Studies

Frequently Asked Questions

How does the 'fail-safe' mechanical locking work?

What is the difference between the 'Bottom Inlet' and 'Side Inlet' solutions?

Can these modules be used for applications other than CNC machining?

What maintenance is required for the zero-point modules?

How do I integrate the system for automated position monitoring?

How do I choose the right module size (85 / 120 / 160 / 195 mm)?

Which pull stud should I use, and how important is stud quality?

What air quality / filtration is recommended for stable long-term operation?

Can I retrofit an existing fixture or vise to a zero-point system?

Resources & Downloads

Product Data & Evaluation Checklist

Use this checklist to validate repeatability, pull-down force, and automation fit during supplier evaluation.

Key specifications

| System components | Receiver modules + pull studs + mounting plate/pallet (configurable) |

|---|---|

| Repeatability | Typical targets down to ≤ 0.003 mm (application-dependent) |

| Locking concept | Fail-safe mechanical locking; pneumatic/hydraulic release options |

| Changeover focus | Quick fixture/pallet swaps for 3-axis & 5-axis machining |

| Wear surfaces | Hardened interfaces on critical locating and locking areas |

| Options | Manual / pneumatic / hydraulic, multiple receiver sizes & stud patterns |

Tip: share your part material, machine model, and target takt time. We’ll propose the right configuration and measurable targets.

Compatibility & standards

- Integrates with pallets, tombstones, vises, chucks, and custom fixtures.

- Layout can be designed for clearance, chip flow, and coolant access.

- Suitable for APC/robot cells with clamp confirmation and safe sequencing.

Measured outcomes (before → after)

- Setup time: minutes or seconds instead of manual re-indicating (process dependent).

- Stable datum after re-clamp: reduced probing time between operations.

- Lower scrap: fewer mis-location and tilt-related issues on multi-op jobs.

Workholding configuration

- BOM definition: receiver quantity, stud type, mounting hardware, porting (if applicable).

- Locator strategy: datum faces, pull-down direction, anti-rotation features.

- Fixture stack-up: plate/pallet → receiver → fixture/vice/chuck → part (verify rigidity).

Evidence & proof

- Fixture layout drawing (PDF/CAD snippet) showing receiver spacing and datum scheme.

- On-machine photos/videos of clamp/unclamp and pallet swap sequence.

- Inspection excerpt: re-clamp repeatability or probing repeat test (sample available).

Delivery & support

- Configuration proposal within 24–48h after receiving part info and machine constraints.

- Spare parts support: studs, seals, receiver components; maintenance checklist included.

- Optional FAT video before shipment for key assemblies.

Complete Your System

Zero-Point Clamping Plates

The ideal foundation. Our plates come with modules pre-installed for easy setup on any machine.

View Details →

Positioning Pull Studs

The crucial counterpart to our modules. Precision-ground for perfect engagement and repeatability.

View Details →

Automatic Pallet Changer

Maximize machine uptime with a fully integrated system built around our core technology.

View Details →

(7).png?updatedAt=1754553737609)