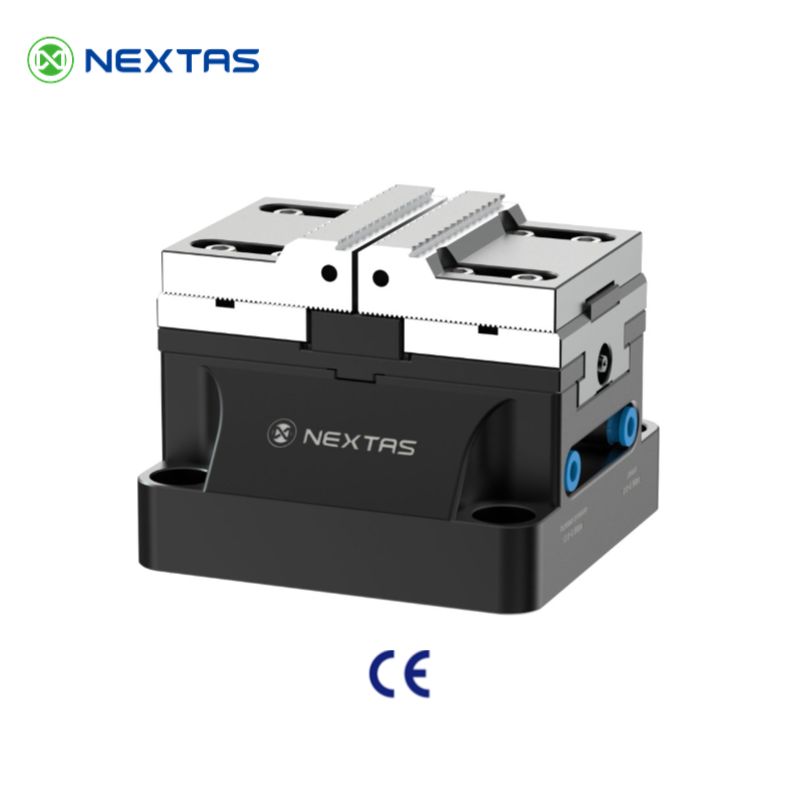

Key Technical Specifications

| Parameter | Specification (Model: NPV-160) |

|---|---|

| Jaw Width | 160 mm |

| Max Opening | 300 mm |

| Clamping Force (at 6 bar) | 4000 kgf |

| Repeatability | ≤0.01 mm |

| Actuation | Pneumatic (Pneumatic-Hydraulic Booster) |

| Recommended Air Pressure | 5 - 7 bar |

| Body Material | FCD60 High-Tensile Ductile Iron |

| Weight | 65 kg |