Enter your email address to request the brochure. Due to time zone differences, we’ll email it the next business morning (GMT+8, Beijing Time).

High-Precision 5-Axis Self-Centering Vise

Engineered for 5-Axis & Automation

The NextasTech Self-Centering Vise is the ultimate workholding solution for modern 5-axis machining and automated production. Its innovative design provides exceptional clamping rigidity and high repeatability, while the compact form factor minimizes interference, maximizing tool access to the workpiece. It is a cornerstone for any enterprise looking to boost efficiency and precision.

Core Advantages

- High Repeatability: Guarantees a centering accuracy of ≤.01mm and repeat clamping accuracy of ≤.02mm for consistent, high-quality results.

- Powerful & Stable Clamping: Unique mechanism delivers strong, stable holding power (up to 35kN), suitable for heavy-duty cutting.

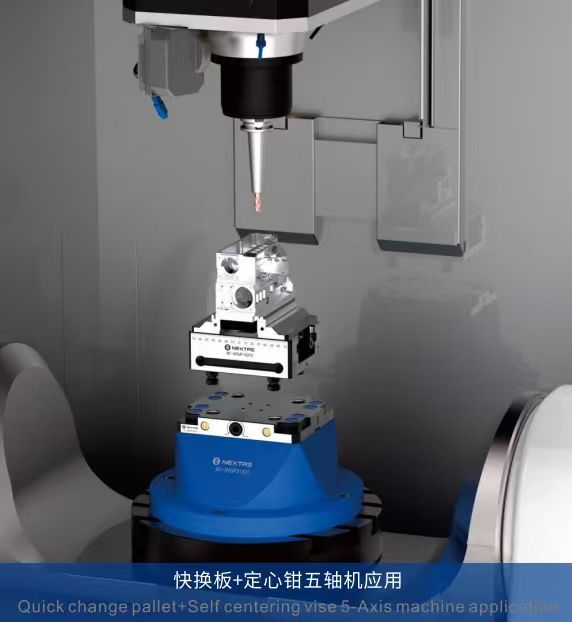

- Optimized for 5-Axis: Compact, symmetrical design minimizes tool interference, providing maximum accessibility for complex part machining.

- Automation Ready: Features clamping grooves for robotic grippers and is compatible with zero-point systems for rapid, automated changeovers.

In-Depth Product Details

Discover the engineering excellence behind our Self-Centering Vise.

Key Technical Specifications

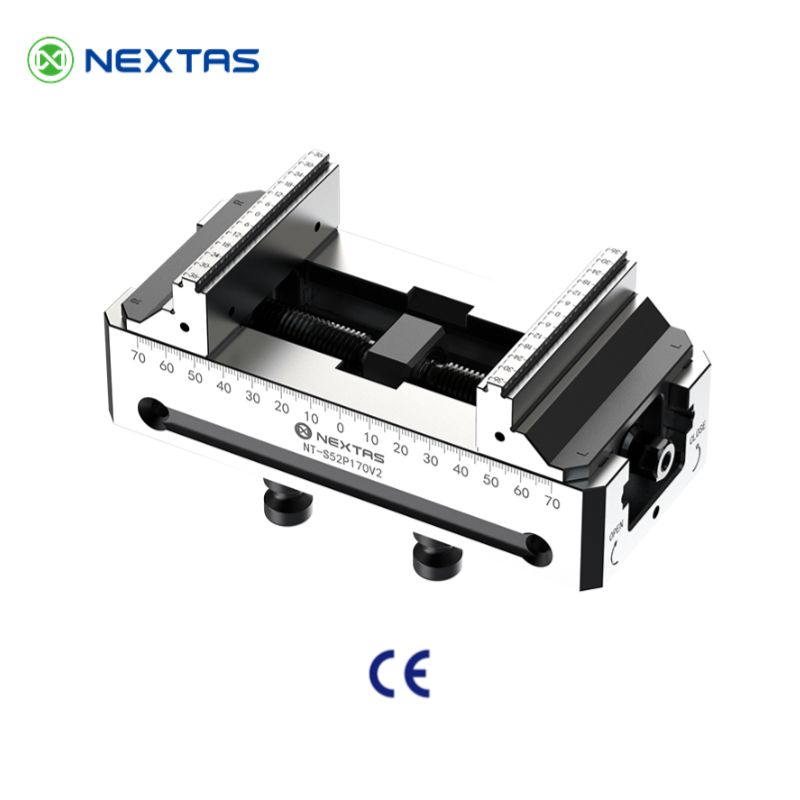

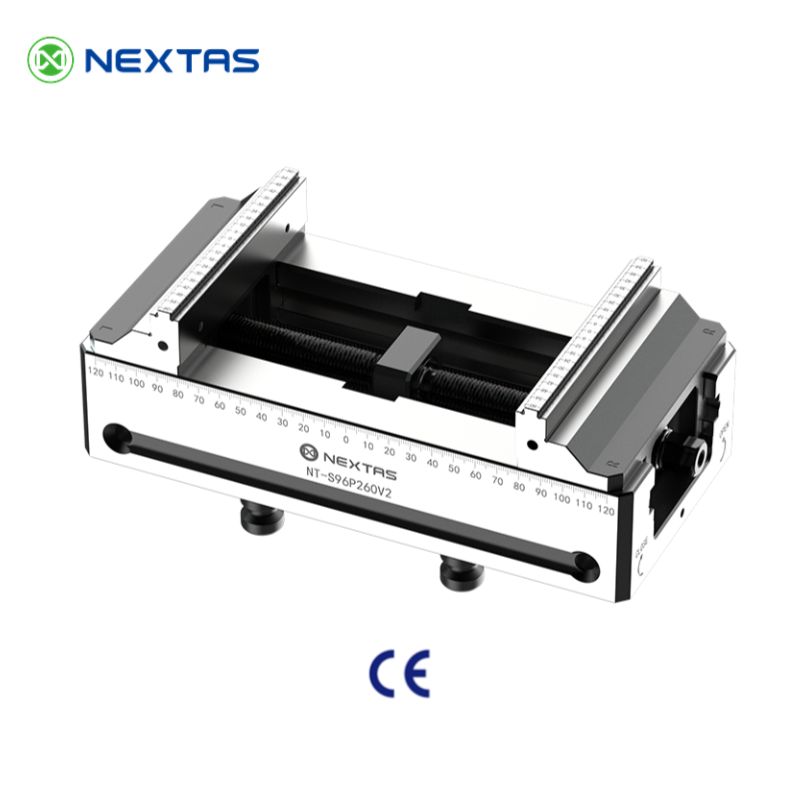

| Parameter | Model: NT-S52P170V2 | Model: NT-S52P210V2 |

|---|---|---|

| Vise Width | 77 mm | 125 mm |

| Max Clamping Range | 0 - 160 mm | 0 - 200 mm |

| Max Clamping Force | 14 kN | 20 kN |

| Repeatability | ±0.02 mm | ±0.02 mm |

| Body Material | High‑Strength Tool Steel (HRC 50±5) | High‑Strength Tool Steel (HRC 50±5) |

| Actuation | Manual (Torque Wrench) | Manual (Torque Wrench) |

| Weight | 3.8 kg | 10.8 kg |

Jaw Specifications & Clamping Range

| Jaw Type | Clamping Range (NT‑S52P170V2) | Clamping Range (NT‑S52P210V2) |

|---|---|---|

| Standard Jaws | 10 - 170 mm | 20 - 210 mm |

| Serrated Jaws | 20 - 180 mm | 30 - 220 mm |

| V‑Jaws | Ø 10 - 100 mm | Ø 20 - 150 mm |

Jaw & Grip Strategy Matrix

Match jaw style to material, surface condition, and cutting load. The matrix below is a practical starting point for selecting jaws on a 5-axis self-centering vise (and for repeatable automation setups).

| Workpiece & material | Goal / operation | Recommended jaw & grip method | Why it works (notes) |

|---|---|---|---|

| Rough stock, castings/forgings (steel/iron) | Aggressive roughing, high torque | Serrated jaws + longer grip length | Serrations bite into scale; longer engagement improves stability on 5‑axis tool access. |

| Aluminum / soft alloys (finished surfaces) | Finish milling with cosmetic surfaces | Machined soft jaws (custom pocket) | Pre-machined pockets distribute load and avoid jaw marks; great for high-mix CNC milling. |

| Thin-wall parts (rings, housings) | Prevent distortion while holding tolerance | Soft jaws + relief cut / support pads | Controlled contact area reduces deformation; probe a datum after clamping for repeatable offsets. |

| Round bar / shafts | Keep true centerline for 5-axis ops | V‑jaws or V‑blocks on soft jaws | Self-centers round stock and improves concentricity for multi-side machining. |

| Symmetrical prismatic parts | Fast changeovers, repeatable datum | Standard jaws + locating step / stop | A consistent stop surface improves part-to-part repeatability for pallet and robot loading. |

| Hard materials (tool steel, titanium) | Resist slip under heavy cuts | Serrated or hardened jaws + conservative depth of grip | Higher friction + safer grip depth lowers risk of micro-slip that shows up as tolerance drift. |

Repeatability Drivers & Quick Checks

Repeatability is a system result (interface + vise + jaws + process). Use the checks below to stay on track when you’re chasing tight tolerances on 5‑axis workholding.

| Driver | Quick check | What it affects |

|---|---|---|

| Mounting interface (zero-point / pallet / table) | Clean mating faces; confirm seating and pull-down | Datum repeatability, especially after changeovers |

| Torque consistency | Use the same torque tool and procedure each time | Clamping force stability and part shift risk |

| Jaw condition & alignment | Inspect jaw faces; verify parallelism/contact pattern | Part tilt, jaw marks, and surface finish |

| Chip control | Blow off jaw bed and workpiece before every clamp | The #1 cause of sudden repeatability loss |

| Grip length vs cutting load | Increase grip length for heavy roughing / long tool reach | Chatter, micro-slip, and dimensional drift |

| Thermal behavior | Re-check after warm-up; avoid measuring immediately after a jaw swap | First-article variation and drift over long cycles |

Engineered for Precision and Efficiency

The NextasTech self-centering vise is a cornerstone of modern CNC machining. We use high-strength alloy steel, precision-ground and heat-treated, to ensure maximum rigidity and durability. Its core self-centering mechanism, driven by a high-precision lead screw, guarantees that the workpiece remains perfectly centered during clamping, which is critical for parts requiring high-precision symmetrical machining.

Modularity and Flexibility

Our vise system supports a wide range of standard and custom jaws, providing the optimal clamping solution for everything from raw castings to finished parts. The quick-change jaw design allows you to reconfigure your setup in minutes, drastically reducing setup time and increasing machine uptime.

Rock-Solid Stability

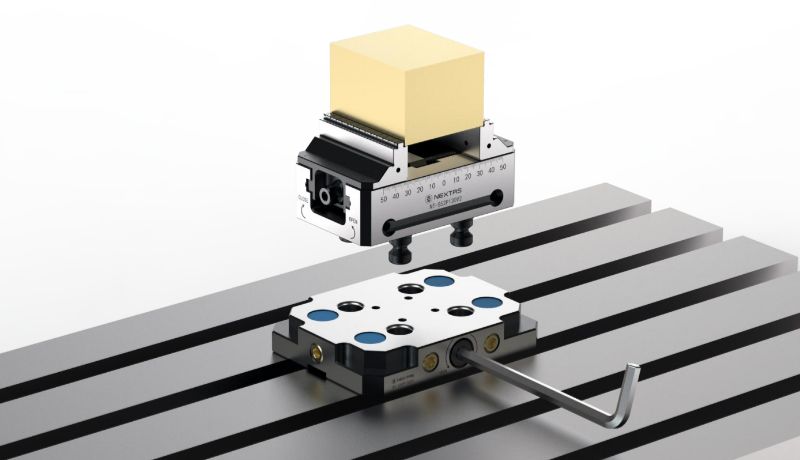

The vise base is designed for seamless compatibility with our zero-point clamping systems, enabling fast and precise mounting. Once installed, the vise forms a rigid unit with the machine table, effectively dampening vibrations even under high-speed, high-feed cutting conditions to ensure superior surface finish and dimensional accuracy.

Enhanced Accessibility

The compact and streamlined design provides maximum accessibility to the workpiece, especially in complex 5-axis machining operations. This allows for shorter tool lengths, reducing vibration and improving cutting performance.

Technical Diagrams

Detailed drawings and specifications for integration.

Application Cases & Solutions

See our vise in action across various industries and setups.

5-Axis Linkage & Complex Surface Machining

The compact design of the NextasTech self-centering vise provides excellent tool accessibility for 5-axis machining. Whether for impellers, molds, or complex structural parts, it ensures interference-free processing, achieving high-efficiency, high-precision surface machining.

Automation Integration & Mass Production

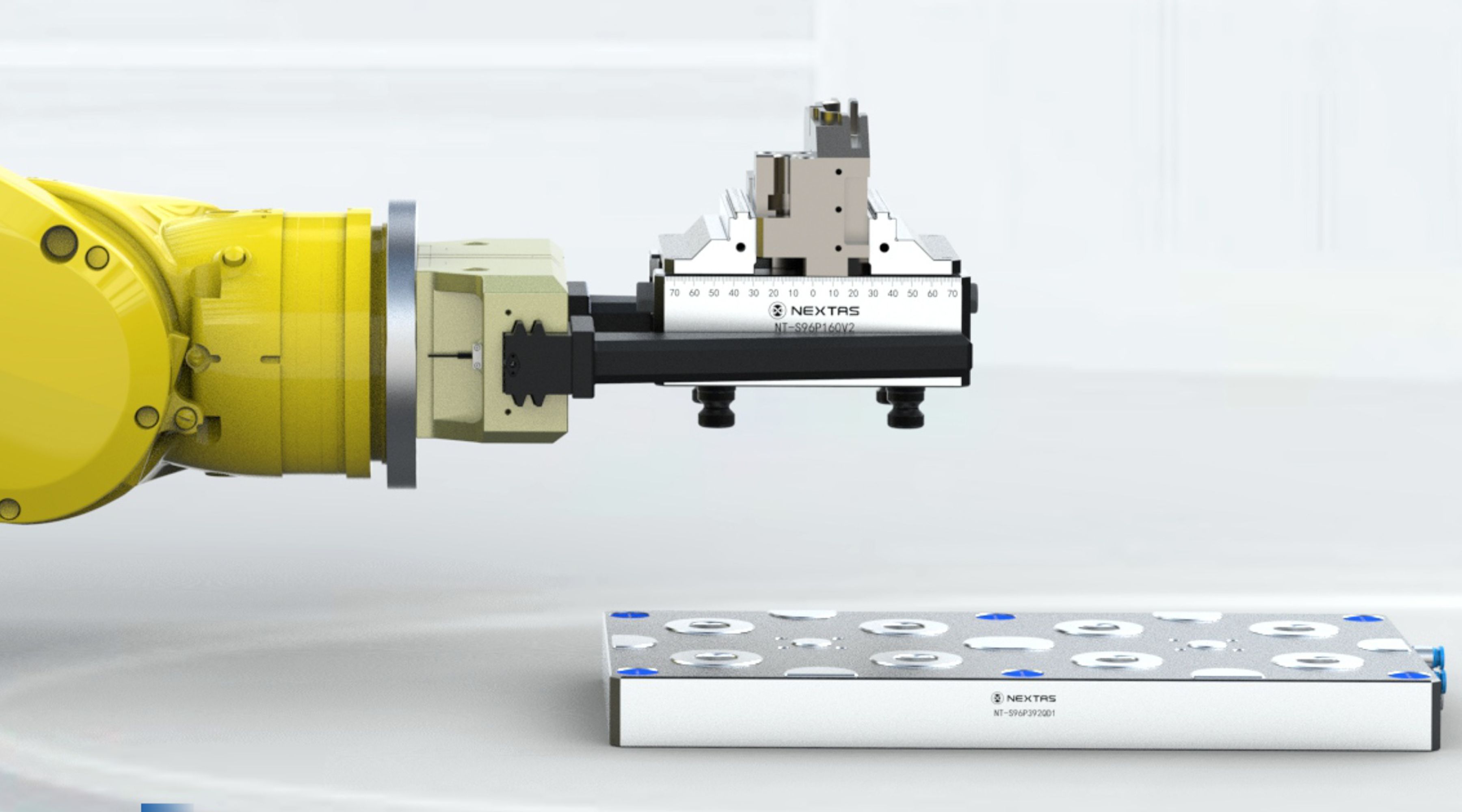

Robotic Arm Integration

The gripping interface on the side of the vise allows for seamless integration with robotic arms, enabling automated workpiece loading and unloading for a 24/7 unmanned production line.

Multi-Vise Array

Arranging multiple vises on the machining center's worktable allows for the processing of multiple workpieces in a single setup, significantly boosting production efficiency.

Paired with Pallet Changer Systems

Mounting the vise on a standardized pallet allows for offline pre-setup, drastically reducing machine downtime and increasing equipment utilization.

Versatile Workpiece Clamping Capabilities

Irregular Workpieces

By using special jaws, it can securely clamp various irregularly shaped workpieces such as castings and forgings, providing a stable machining base.

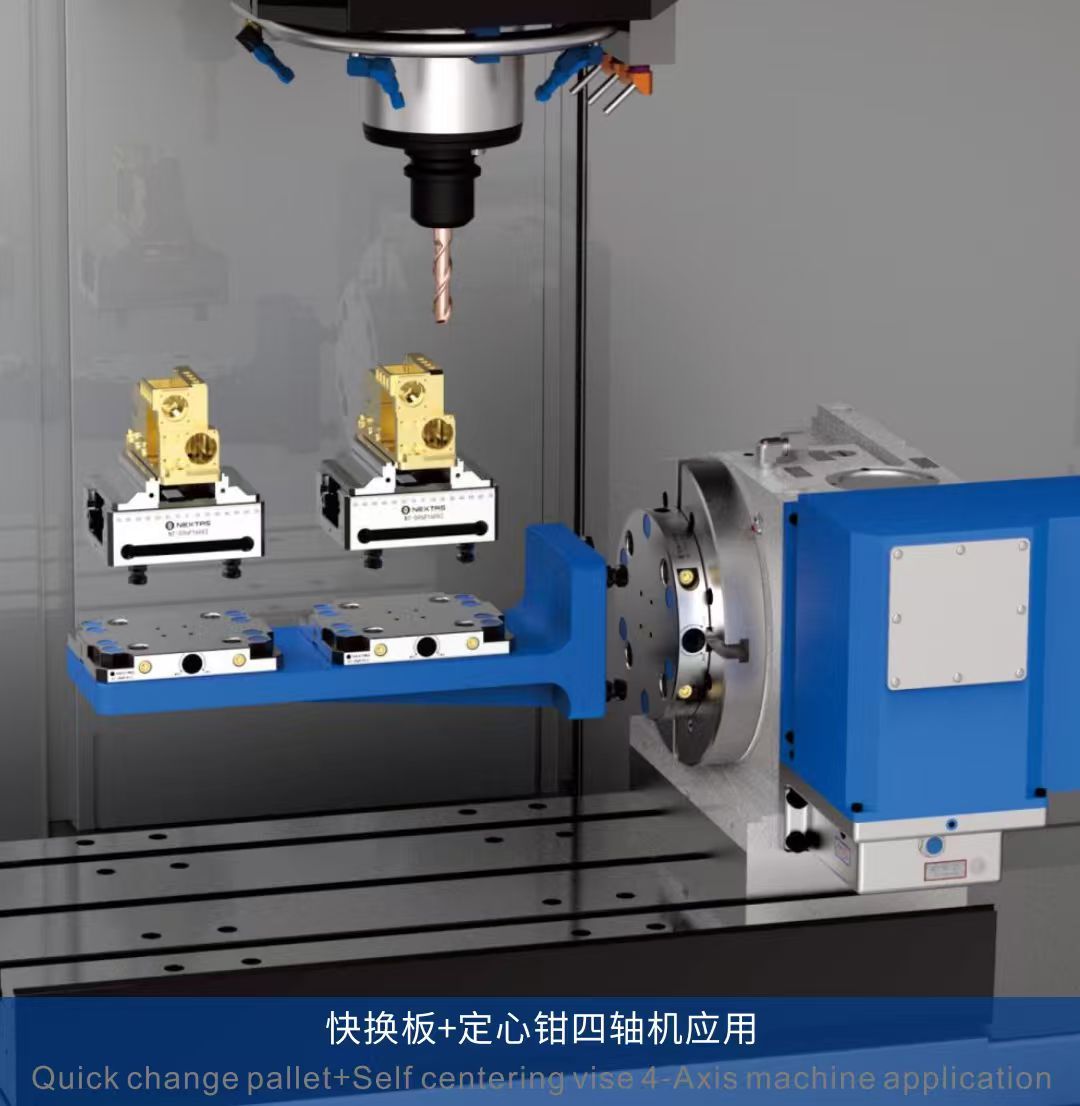

4th-Axis Application

The vise's lightweight and high-rigidity features also make it suitable for mounting on a 4th-axis rotary table for multi-sided component machining.

Round Bar Workpieces

Paired with V-jaws, it can easily achieve precise and stable center clamping of round bar workpieces, suitable for machining shaft-like parts.

Real-World Case Studies

Precision and performance delivered to our clients.

Built for Production. Backed by Real Support.

Engineers care about repeatability. Procurement cares about verification. This section gives both teams what they need.

Modular Workholding & Quick-Change Jaws

Designed for a wide range of parts and setups. The modular architecture supports special jaws and a quick-change jaw design—so you can switch from castings/forgings to finished parts without wasting spindle time.

- ●Supports irregular workpieces (castings, forgings) with special jaws

- ●Fast jaw swaps for small-batch + mixed-model production

- ●Ideal with pallets / zero-point / automation cells

Engineering + After-Sales You Can Rely On

Need more than a standard vise? We support customization and provide one-to-one technical service. For complex projects, we can help with fixture solution planning, process planning, and application guidance.

- ●15+ years R&D experience (team background)

- ●Customized fixture solution based on your part geometry

- ●One-stop technical support: fixture + process + application guidance

Verified Supplier Credentials

We maintain a verified supplier presence on Made-in-China. This gives procurement teams an extra layer of confidence for supplier due diligence and compliance review.

- ●Manufacturer/Factory & Trading Company profile

- ●Certificates available on request (varies by model and product line)

- ●Platform record shows membership level / supplier rating / recent transaction history

Video Demo (Quick Overview)

A short demo helps your team confirm size, handling, and typical applications before requesting CAD files or a quote.

Setup Guide & Machining Best Practices

Faster setup, cleaner datums, and more stable cutting—especially on 5-axis.

1) Mount & Reference

For repeatability, treat the vise like a fixture: mount it once, qualify it, and reuse the same reference every changeover.

- ●Use a zero-point/pallet interface when available to eliminate re-indicating.

- ●Touch off the vise centerline once and save as a macro/work offset.

- ●For torque-heavy cuts, add an anti-rotation feature in the jaw design.

2) Jaw Choice = Part Quality

Matching jaws to material and surface condition is the easiest way to prevent slip, distortion, and chatter.

- ●Serrated jaws for castings/forgings and rough stock.

- ●Soft jaws for finished surfaces and thin-wall parts.

- ●V-jaws for round bars and shaft-like components.

3) Clamp, Verify, Run

A quick verification routine helps you protect tolerances while keeping cycle time low.

- Clean jaw faces + bed (chips are the #1 repeatability killer).

- Clamp using the recommended torque tool / module.

- Probe a reference feature (or indicate) for first-article confirmation.

- For long runs: re-check after warm-up and after jaw swaps.

Setup & Verification Checklist (for tight-tolerance CNC)

A short, repeatable routine helps a self-centering vise deliver stable results across pallets, shifts, and operators.

| Step | What to do | Tip for 5-axis / automation |

|---|---|---|

| 1. Prep | Wipe interface + jaw bed; remove burrs and chips | Treat it like a fixture: cleanliness = repeatability |

| 2. Mount | Seat on table/pallet/zero-point; apply specified tightening pattern | If you use a zero-point system, avoid re-indicating every changeover |

| 3. Qualify | Probe/indicate vise centerline once; store as a work offset/macro | Makes multi-pallet and robot loading predictable |

| 4. Clamp | Use consistent torque; confirm full jaw contact | For thin walls: use soft jaws + support pads |

| 5. Verify | Probe a reference feature (first-article) | Log the offset; watch for drift after warm-up |

| 6. Run & monitor | For long cycles: re-check after jaw swaps or tool changes | Small checks prevent big scrap batches |

Maintenance & Service Schedule

Simple care keeps the lead screw, jaw guidance, and contact surfaces performing like a precision workholding system.

| Interval | Task | Why it matters |

|---|---|---|

| Each shift | Clean chips from jaw bed and interfaces | Prevents seating errors and clamp inconsistency |

| Weekly | Inspect jaw faces; check for dings, wear, or raised burrs | Protects surface finish and reduces part movement |

| Monthly | Lightly lubricate moving contact points per your shop standard | Reduces friction and improves clamping smoothness |

| Quarterly | Verify centerline/reference with a quick indicating/probing routine | Catches gradual drift before it becomes a quality issue |

| As needed | Replace worn jaws / pads; refresh soft jaw pockets | Keeps grip reliable for high-mix production |

Typical 5-Axis Workflow

If you machine complex parts (aerospace, medical, precision molds), this workflow keeps access high and collisions low.

Roughing

Use serrated jaws + higher clamp force. Keep grip length conservative for stability.

Finishing

Switch to soft jaws or precision pads. Probe critical features to protect tolerance stack-up.

Common Use Cases

- High-mix, low-volume machining where changeover speed matters.

- 5-axis parts needing maximum tool clearance and fewer re-clamps.

- Automation cells with pallets / zero-point / robotic handling.

- Thin-wall components where controlled clamping prevents distortion.

Choose the Right Self‑Centering Vise

A simple checklist for selecting model size, jaw set, and mounting interface—so you get predictable accuracy on day one.

Model guidance

Use your part envelope, cutting load, and changeover frequency to decide.

| Model | Best for | Notes |

|---|---|---|

| NT‑S52P170V2 | Compact parts, 5‑axis clearance, lighter rotary setups | Fast handling, lower mass, excellent for dense multi‑vise layouts |

| NT‑S52P210V2 | Larger parts, heavier cutting, more jaw travel | Higher clamping force and envelope for wider part families |

If you share a drawing + material + target tolerance, we can recommend jaw style and grip strategy.

What to send for a fast quote

- Part size range (min/max), material, and rough/finished surface condition

- Machine type (3‑axis/5‑axis) + table/pallet interface (52/96 mm etc.)

- Batch size and changeover frequency (prototype vs production)

- Any automation plan (robot loading / pneumatic or hydraulic actuation)

Related technical reading

More context for engineering teams evaluating 5‑axis workholding and repeatable setups.

Self‑Centering Vise: How it improves consistency

Mechanism overview, repeatability, and jaw strategy.

5‑Axis + Self‑Centering Vise for complex machining

Tool access, fewer re‑clamps, and collision risk reduction.

Zero‑Point compatibility: faster changeovers

Why standard interfaces matter for pallets and automation.

Frequently Asked Questions

Your questions, answered.

How does the self-centering mechanism handle rough or asymmetrical workpieces?

What is the recommended maintenance for maintaining the ≤.01mm centering accuracy?

Can this vise be integrated with a zero-point clamping system, and how does it mount?

You mentioned 'Automation Ready'. What specific features support this?

Will I experience jaw lift when clamping a workpiece?

Is it suitable for hobbyists or only professionals?

Can jaw pads be replaced if worn?

What causes uneven clamping, and how do I fix it?

Is it compatible with CNC machines?

Resources & Downloads

Product Data & Evaluation Checklist

Buyers compare vises by accuracy, jaw range, 5-axis clearance, and how fast you can switch setups and jaws.

Key specifications

| Vise type | 5-axis self-centering vise for automation & high-mix production |

|---|---|

| Accuracy goal | Typical machining targets around 0.02 mm (setup dependent) |

| Interface standard | Supports common 52/96 mm spigot hole standards (model dependent) |

| Jaw options | Quick-change jaws; multiple jaw styles for different workpieces |

| Clamping range | Defined by jaw set; configurable for part families |

| Automation fit | Pneumatic/robot-friendly configurations available |

Tip: share your part material, machine model, and target takt time. We’ll propose the right configuration and measurable targets.

Compatibility & standards

- Designed for 5-axis accessibility: low profile and improved tool clearance.

- Pairs with zero-point quick-change systems to reduce fixture swaps.

- Supports repeat clamping with consistent center reference for symmetric parts.

Measured outcomes (before → after)

- Setup time: fewer re-indicating steps when switching part sizes within a family.

- Scrap reduction: less mis-clamp and improved centering repeatability.

- Unattended machining: stable clamp plus automation interfaces (options).

Workholding configuration

- Jaw selection: serrated/soft jaws, step jaws, or custom jaws per part geometry.

- Locator points: define datums and anti-rotation features for torque-heavy cuts.

- Workpiece plan: grip length and distortion control for thin walls.

Evidence & proof

- Jaw drawing/CAD snippet and clamping range chart for your part family.

- On-machine photos of 5-axis clearance and toolpath access.

- Inspection excerpt: repeated clamp test and parallelism/runout checks.

Delivery & support

- Application review: send part drawings for jaw recommendation and grip strategy.

- Spare jaw program: prepared jaw sets for faster SKU switching.

- Support: setup checklist and troubleshooting for repeatability issues.

Related Products

Zero Point Clamping System

Achieve rapid changeovers with ±0.002mm repeatability, boosting production efficiency.

View Details →E-Series Chuck

Versatile and precise chuck for a wide range of turning applications.

View Details →Automatic Pallet Changer

Streamline your workflow with automated pallet changes for continuous production.

View Details →