Pallet Changer System

Tailored Solutions for Industrial Efficiency

Pallet Changer System is a tailored solution engineered to resolve pain points in industrial manufacturing. Refined through iterative R&D, it adapts to diverse application needs across multiple sectors. The product line is categorized into two core series—Manual Pallet Changer System and Automatic Pallet Changer System—empowering enterprises to cut costs, boost efficiency, and enhance market competitiveness.

Core Technical Highlights

- Tapered-Surface Positioning: Ensures stable clamping and high repeat positioning accuracy.

- Pressurized Clamping: Piston-driven mechanical self-locking structure delivers high-strength output.

- Smart Detection: Built-in air tightness detection verifies positioning and feeds back to CNC.

- Self-Cleaning: Automatic air-blow ports remove debris from datum surfaces for consistent accuracy.

CNC Pallet Changer System: higher spindle uptime, faster setup, better repeatability

A pallet changer system (manual or automatic) lets you prepare the next job outside the machine while machining continues. For job shops running high-mix, low-volume (HMLV) production, this means less waiting, fewer re-indicating steps, and a more predictable process from first piece to last piece.

Reduce setup time

Clamp a fixture on the pallet offline, then swap pallets in seconds/minutes depending on configuration—ideal for frequent changeovers.

- Quick change worktable for VMC / 3-axis milling

- Repeatable pallet references to reduce re-indicating

- Standardized fixtures and pallet plates across jobs

Improve accuracy & consistency

Using tapered datum positioning and verified clamping feedback, the pallet seats the same way every time for stable machining results.

- Micron-level repeatability (model dependent)

- Air tightness / seating detection for safer automation

- Self-cleaning air blow keeps datum surfaces clean

Enable unattended machining

Automatic pallet changing is a practical entry point for CNC automation—often simpler than adding a full robot cell.

- PLC + HMI control with standard I/O / M-code signals

- Supports pallet queue workflows and repeat setups

- Integration path to pallet pool / FMS and MES

Where pallet changer systems are commonly used

Pallet changer systems are popular in aerospace, automotive, mold & die, medical, and general precision parts machining—especially when multiple fixtures, vises, or tombstones are rotated through the same machine. They are also widely used for multi-part batching and lights-out CNC machining strategies.

Want a fast recommendation?

Send your VMC model, table size, typical part weight, and your target changeover time.

Talk to an engineerManual vs. Automatic Pallet Changer: choosing the right configuration

Both systems use repeatable pallet positioning to speed up setups. The best choice depends on your mix of parts, operator time, and how far you want to push automation.

Manual Pallet Changer System

Best for shops that want faster changeovers with minimal automation and a lower entry cost.

- Great for frequent fixture swaps on 3-axis VMCs

- Operator-controlled pallet exchange (simple workflow)

- Ideal when part volumes are moderate and staffing is stable

Automatic Pallet Changer System (APC)

Best for high throughput, HMLV production, and unattended machining where spindle uptime is the main KPI.

- Automated pallet swap cycle with interlocks & confirmation

- Supports pallet queue logic and cell-style workflows

- Integration-ready for MES/SCADA, pallet pool, or robot loading

| Selection factor | Manual | Automatic (APC) |

|---|---|---|

| Typical goal | Reduce setup time & standardize fixtures | Maximize spindle uptime & enable unattended runs |

| Changeover workflow | Operator-assisted pallet exchange | Automated cycle with sensors and interlocks |

| Best for | Job shops, prototype work, frequent part changes | Batch production, HMLV at scale, lights-out machining |

| Integration | Simple; minimal CNC signals | PLC/HMI; supports I/O, network protocols (model dependent) |

Pallet Style Options

Choose the pallet top that matches your fixture strategy—T-slot pallets for flexible clamping, magnetic pallets for fast loading of flat parts, aluminum pallets for lightweight handling, and zero-point pallets for repeatable quick change workholding. Standardizing pallet plates is a proven way to speed up CNC setups and support pallet pool workflows.

Aluminium Pallet

Material: Aluminium Alloy

Size: Adaptable to machine stroke

T-Slot Pallet

Material: Martensitic Stainless Steel

Size: Adaptable to machine stroke

Magnetic Pallet

Material: Martensitic Stainless Steel

Size: Adaptable to machine stroke

Zero Point Pallet

With Zero Point Positioner

Material: Martensitic Stainless Steel

Manual Pallet Changer System

The manual pallet changer is a practical way to reduce setup time on a vertical machining center (VMC). Operators can clamp a fixture pallet offline and perform a quick pallet swap, making it ideal for frequent part changes, prototypes, and short-run CNC machining.

Key Advantages

-

Stable Loading & Unloading

Flexible dual-station design supports front or side-mounted loading, enabling high-mix, low-volume production.

-

Quick Loading & Processing

Completes full layout clamping and rapid retooling in just a few seconds.

-

Efficiency & Utilization Boost

Offline loading and fast machine transfer enhance equipment utilization significantly.

-

Safe & Labor-Saving

External clamping allows quick, effortless positioning via simple operation, reducing labor intensity.

Technical Specifications (Manual)

| Control System | Manual push control |

| Compatible Systems | Mitsubishi, FANUC, Brother, KND, etc. |

| Delivery Load | 100 Kg |

| Air-tightness Range | ± 0.01 mm |

| Max Load | 300 Kg |

| Specification | V4 Positioning Datum |

| Repeat Accuracy | < 0.005 mm |

| Clamping Force | 40,000 N |

| Max Lifting Load | 850 Kg |

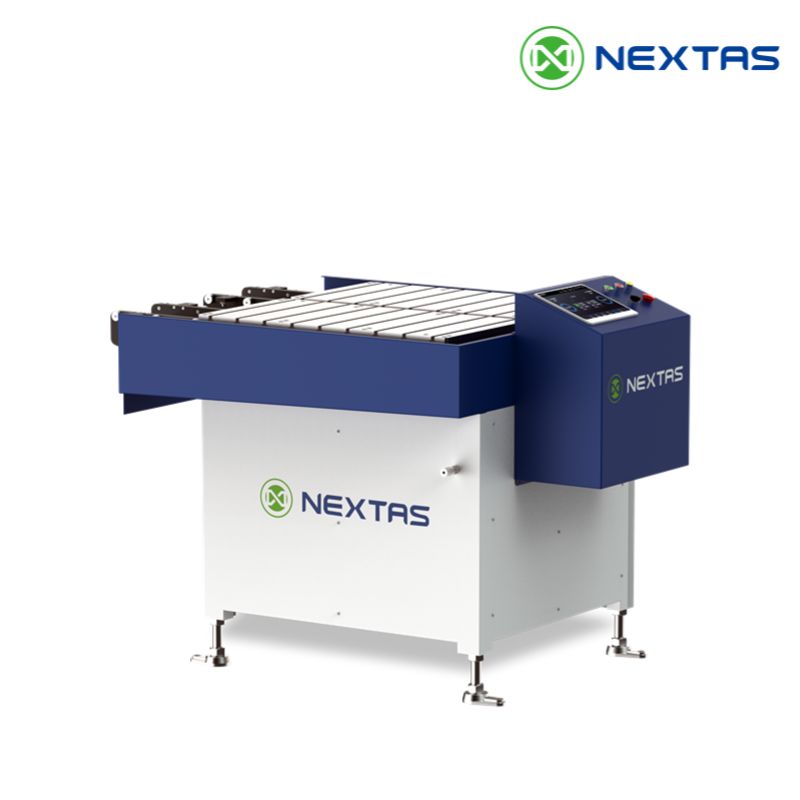

Automatic Pallet Changer System

A CNC automatic pallet changer (APC) boosts spindle uptime by automating the pallet swap cycle and confirming safe clamping before machining starts. It is well suited for HMLV production at scale, batch machining, and lights-out workflows where repeatability, safety interlocks, and controller integration matter.

Key Advantages

-

Robust External Clamping

High-strength rigid bracket structure supporting custom heavy-load configurations. Compact footprint with integrated safety protection.

-

Micron-Level Precision

Adopts zero-point positioning principles, consistently maintaining <0.005mm repeat accuracy for stable, ultra-precise clamping.

-

Broad VMC Compatibility

Compatible with multiple VMC brands. Supports front or side pallet exchange with customizable pallet sizes.

-

Smart Integrated Control

Self-developed control system supports MES/SCADA integration for unattended automated loading, management, and data visualization.

Technical Specifications (Automatic)

| Control System | NextasTech |

| Compatibility | Mitsubishi, FANUC, Brother, KND, etc. |

| Communication | EtherNet/IP, ModbusTCP, Socket, PROFINET |

| System Features | Dual-station, product editing, output monitoring, capacity statistics |

| Delivery Speed | 300 mm/s |

| Movement Accuracy | 0.02 mm |

| Max Load | 2,000 Kg |

| Specification | V6 Positioning Datum |

| Repeat Accuracy | < 0.005 mm |

| Clamping Force | 60,000 N |

Engineering & Integration Guide for Automatic Pallet Changers

Planning an APC for a pallet pool, robot‑tended cell, or unattended machining line? Use the guide below to size capacity, define control I/O and safety interlocks, and estimate cycle‑time impact—so your pallet changer stays repeatable and integration is low‑risk.

Capacity & Pallet Sizing Worksheet

Define pallet size, payload, and moment load early—especially for 5‑axis fixtures—so swap accuracy and repeatability don’t drift over time.

| Parameter | What to define | Why it matters |

|---|---|---|

| Pallet size & top standard | Usable area, locating features, grid / T‑slot / zero‑point top | Determines fixture layout, flexibility, and changeover speed |

| Payload (kg) | Pallet + fixture + part mass (include coolant) | Affects dynamics, bearings, and safe acceleration / deceleration |

| Overturning moment | CG offset vs. locating plane (X/Y/Z) | Critical for repeatability under heavy cuts and high feeds |

| Required repeatability | Target position repeatability and re‑indicating allowance | Sets locating strategy and verification method |

| Coolant & chips | Flood / through‑spindle, chip type, chip evacuation path | Impacts sealing, sensors, and long‑run reliability |

| Automation scenario | Robot, pallet pool, FMS, lights‑out batch size | Defines cycle strategy and confirmation requirements |

Controller I/O & Safety Interlocks

A clean handshake (M‑codes, I/O, and confirmations) prevents mis‑loads and supports unattended pallet swaps.

| Signal / check | Typical implementation | Notes |

|---|---|---|

| Pallet present | Inductive / RFID / mechanical key | Use dual confirmation if running lights‑out |

| Clamp OK | Pressure switch + position sensor | Avoid relying on pressure only for safety‑critical clamps |

| Unclamp OK | Position sensor | Needed before axis motion / magazine movement |

| Door / guard interlock | Safety relay / PLC | Target appropriate safety level (e.g., PLd/SIL2) |

| Hydraulic / pneumatic pressure OK | Redundant pressure switches | Log pressure trends to predict leaks |

| Robot / magazine ready | Discrete I/O + timeout logic | Define safe states for recovery after E‑stop |

Cycle‑Time & ROI Quick Model

Estimate spindle uptime gain with a simple before/after model. This helps justify an APC versus manual pallet swapping.

| Input | How to use it | Example outcome |

|---|---|---|

| Current setup time per job | Measure indicating + clamping + probing | Baseline for payback |

| Pallet swap time | APC swap + confirmation sequence | Often minutes → seconds |

| Batch size / mix | High‑mix jobs benefit most | More jobs/day with same labor |

| Spindle utilization (%) | Track cutting vs. idle | Target higher OEE with palletized flow |

| Labor rate & shifts | Include overtime / night shift premium | Quantifies saved labor and added output |

| Scrap / rework risk | Track mis‑clamp or mis‑load events | Interlocks + repeatability reduce costly errors |

Preventive Maintenance Plan

A simple maintenance routine keeps repeatability stable for long‑run production (pallet pool / unattended machining).

| Interval | What to check | Why |

|---|---|---|

| Daily | Clean locating surfaces; check chips around reference faces | Chips are the #1 repeatability killer |

| Weekly | Inspect sensors and cables; verify clamp/unclamp confirmation | Prevents false positives and downtime |

| Monthly | Check pressure stability; inspect seals; test interlock chain | Catches leaks and drifting switches early |

| Quarterly | Verify repeatability with a gauge pallet / probe routine | Creates a measurable baseline for QA |

| Annually | Full inspection: bearings, manifolds, wear surfaces | Extends lifecycle and reduces surprise failures |

Automatic Pallet Changer Selection Checklist & Data Guide

Use this checklist to define your CNC pallet changer requirements: pallet size, payload, repeatability targets, controller signals, and safety interlocks. It helps speed up quoting and reduces integration risk.

Key specifications

| System type | Manual / automatic pallet changer (model dependent) |

|---|---|

| Pallet options | Aluminum, T-slot, magnetic, and zero-point pallet styles |

| Automation fit | Designed for pallet pool / robot / unattended workflows |

| Repeat setup | Repeatable pallet location to reduce re-indicating |

| Interface | Customizable for machine table sizes and patterns |

| Safety | Interlocks and confirmation strategy (system dependent) |

Tip: share your part material, machine model, and target takt time. We’ll propose the right configuration and measurable targets.

Compatibility & standards

- Integrates with zero-point systems for repeatable pallet location across machines.

- Supports multiple pallet top standards to match your fixture strategy.

- Suitable for high-mix production requiring frequent pallet swaps.

Measured outcomes (before → after)

- Changeover time reduction: faster job switching and higher spindle uptime.

- Standardization: consistent pallet references reduce setup variation.

- Unattended operation: fewer manual interventions in production schedules.

Workholding configuration

- Pallet spec: size, top interface, and load requirement.

- Machine integration: mounting pattern, guarding, and clearance planning.

- Workflow: pallet queue, identification, and safe clamp/unclamp sequencing.

Evidence & proof

- Cell layout drawing showing pallet flow and safety zones.

- Demo video of pallet swap cycle and reference verification.

- Repeat location test results after multiple pallet changes (sample).

Delivery & support

- System integration review: machine model and layout needed for confirmation.

- Installation/commissioning checklist and operator training notes.

- Service plan: recommended spares and maintenance guidance.

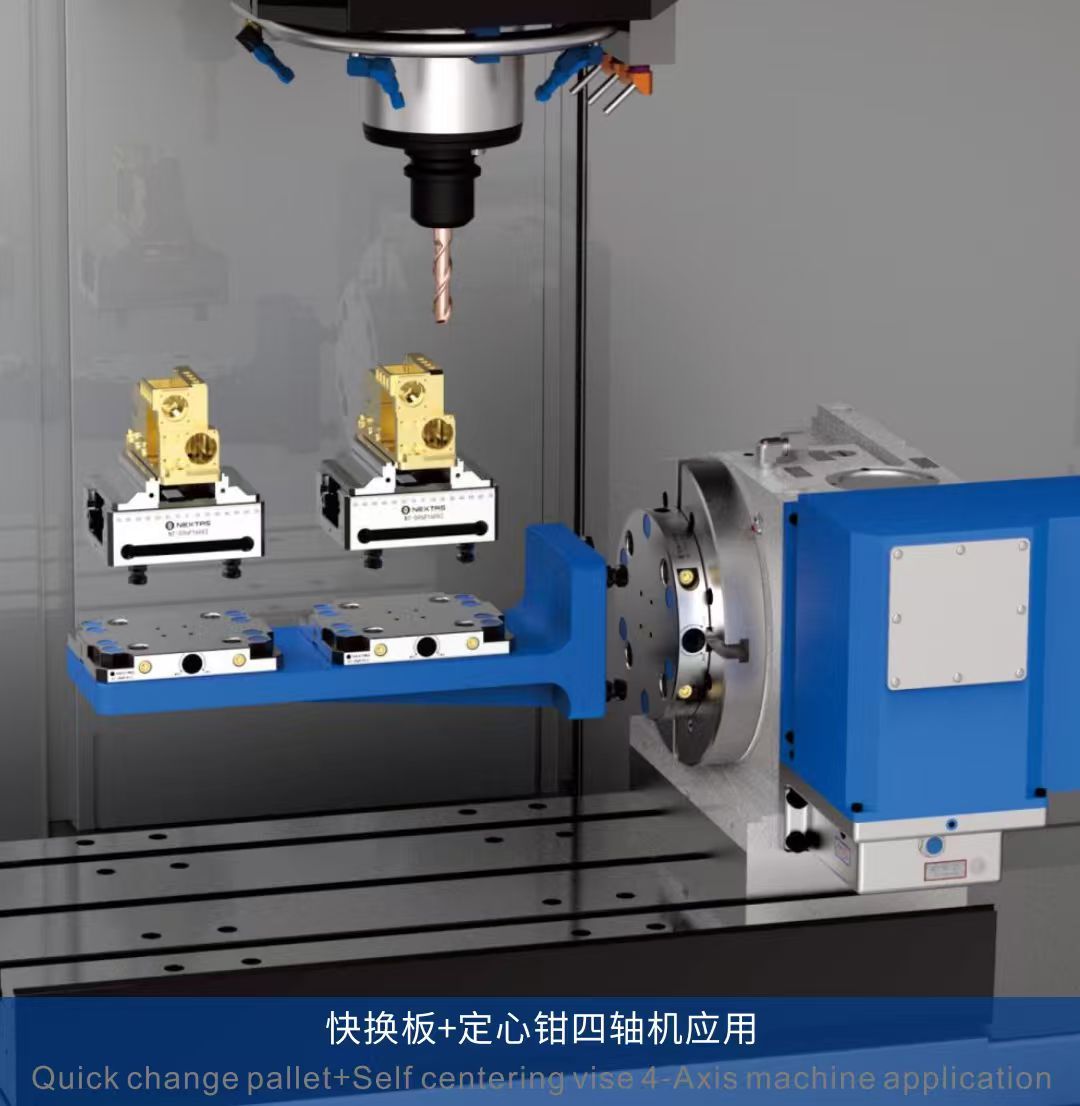

Real-World Applications

From multi-fixture job shops to automated production cells, pallet changer systems help keep the machine cutting. Common applications include milling families of parts on dedicated fixture pallets, running multiple SKUs overnight, and standardizing setups across machines with repeatable pallet references.

Frequently Asked Questions

01 What is an Automatic Pallet Changer (APC) and who is it for?

02 What are the key specifications of the NextasTech APC?

03 Which CNC machine controllers is the APC compatible with?

04 What safety features are included in the APC system?

05 How does the APC handle high-mix, low-volume (HMLV) production?

06 What is the installation and integration process like?

07 What is the typical Return on Investment (ROI) for an APC?

08 Where can I get CAD files or technical documentation?

09 Can the automatic pallet changer integrate with a pallet pool or robot loading?

10 What repeatability can I expect, and how is it verified?

11 What maintenance is needed to keep the pallet changer accurate and reliable?

Related Products

Zero Point Clamping System

Achieve setup times in seconds with maximum repeatability. The core of flexible manufacturing.

View Details →

Self Centering Vise

Ideal for 5-axis machining and automated applications, ensuring the workpiece is always perfectly centered.

View Details →

R-Series Chuck

Robust and versatile pneumatic chuck for heavy-duty applications and automated environments.

View Details →