Enter your email address to request the brochure. Due to time zone differences, we’ll email it the next business morning (GMT+8, Beijing Time).

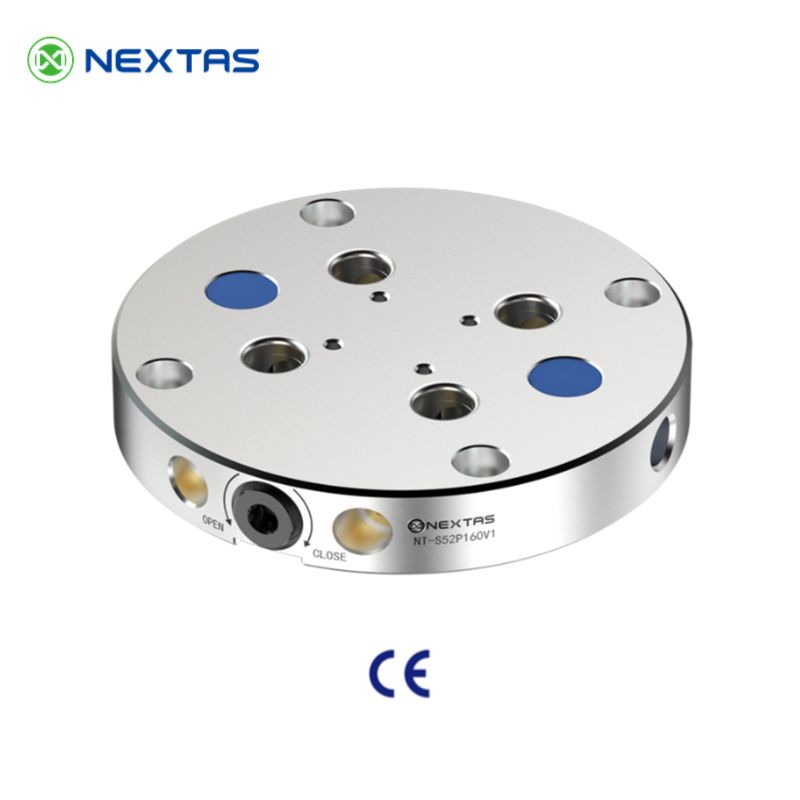

Zero-Point Clamping Plate

The Foundation for Ultimate Flexibility

The NextasTech Zero-Point Clamping Plate is the fastest way to implement a modular, quick-change system on your machine tool. By providing a standardized, precision-ground base with integrated zero-point clamping modules, it transforms your machine bed into a highly flexible and productive platform.

Core Advantages

- Standardized Machine Interface: Instantly create a universal grid on your machine table, allowing any fixture or pallet to be mounted with perfect alignment every time.

- Exceptional Rigidity and Stability: Precision-ground from high-grade materials, our plates provide a solid, stable base that absorbs vibration and withstands heavy cutting forces.

- True Modularity: Available in various sizes and configurations (single, dual, quad-module) to fit any machine table and application, from small vises to large tombstone fixtures.

- Plug-and-Play Implementation: Dramatically simplifies the adoption of a zero-point system. Simply bolt the plate to your machine's T-slots and connect the air supply to start saving setup time.

Plate Specifications

| Parameter | Specification |

|---|---|

| Plate Material | Hardened Stainless Steel |

| Flatness / Parallelism | ≤0.005mm |

| Standard Sizes (L x W) | Refer to catalogue |

| Integrated Modules | 1, 2, 4, or more, depending on plate size |

| Module Spacing | Standard 52mm, 96mm, 200mm grids, or custom patterns |

| Mounting System | Designed for standard T-slot tables or direct mounting |

| Surface Treatment | Corrosion-resistant coating |

Built as a Rock-Solid Foundation

The NextasTech Zero-Point Clamping Plate serves as the crucial link between your machine tool and your workholding. Each plate is meticulously crafted from high-quality, stress-relieved steel or aluminum and precision-ground to achieve exceptional flatness and parallelism. This ensures that the micron-level accuracy of the integrated zero-point modules is perfectly transferred to your workpiece. The plates feature a standardized grid pattern (e.g., 52mm/96mm) and integrated plumbing for pneumatic actuation, making setup clean, simple, and incredibly fast.

52mm/96mm Industry-Standard Module Design

The manual zero point plate adopts a 52mm/96mm industry-standard module design, ensuring strong compatibility with global CNC machining tooling systems. This standardization avoids custom adaptation troubles, enabling seamless integration into both small workshops and large manufacturing setups. The two module sizes meet different workpiece weight and size needs, boosting flexibility in diverse machining tasks. With widely available spare parts, it simplifies maintenance and replacement. For businesses valuing consistency, this design cuts downtime from incompatible tooling, enhancing overall operational efficiency.

How to Choose the Right Zero-Point Clamping Plate

A zero-point clamping plate is more than a “base plate” — it becomes your standardized machine interface. Picking the right configuration upfront helps you get repeatable accuracy, faster changeovers, and a cleaner path to palletization.

1) Plate size & mounting

Match the plate footprint to your table travel and T-slot pattern. Consider clearance for toolpaths, coolant flow, and chip evacuation. For frequent swaps, many shops standardize one “home” plate per machine.

2) Module layout & grid

Choose an industry-standard 52mm/96mm pattern when you want broad compatibility with pallets, vises, and fixtures. Need larger parts or heavier cuts? A wider spread (or additional modules) increases stability and load capacity.

3) Workholding style

If you run high-mix production, prioritize quick-change vises and standardized pallets. For 4/5-axis work, focus on rigidity, Z-height, and repeatable locating — so parts can move from CNC to CMM without re-fixturing.

Zero-Point Plate vs. Traditional T-Slots

| What matters | T-slot setups | Zero-point clamping plate |

|---|---|---|

| Changeover time | Manual indicating & alignment | Swap pallets/fixtures in minutes |

| Repeatability | Operator-dependent | Consistent positioning (when cleaned & maintained) |

| Scalability | Hard to standardize across jobs | Standard interface for pallets, vises, and fixtures |

| Inspection workflow | Often requires re-fixturing | CNC → CMM on the same pallet/zero reference |

If your shop does frequent job changes, short runs, or wants a clear path to automation, a zero-point clamping plate usually pays back by increasing spindle uptime and lowering setup variability.

Installation & Maintenance Checklist

- Mount & level: Bolt the plate to the machine table and verify flat contact. Follow the recommended torque values from the catalog.

- Connect air supply: Use clean, dry air with appropriate filtration. Confirm leak-free connections before production.

- Verify clamping stroke: Test open/close cycles and confirm all modules engage consistently.

- Keep interfaces clean: Chip management is everything. A quick wipe or air blow-off before loading improves repeatability.

- Routine checks: Inspect seals, locating surfaces, and fasteners on a schedule based on your coolant and chip conditions.

Tip: If you plan to expand into pallet pools or automation, standardize plate patterns and pallet interfaces early — it saves rework later.

Plate configuration planner (modules, grid, and use-case)

Use this quick planner when you’re selecting a zero-point clamping plate for CNC changeovers, palletization, or 5-axis fixtures. The goal is to standardize a repeatable interface (plate + pallet/fixture) while keeping tool clearance, chip evacuation, and air routing practical.

| Use case | Recommended layout | Why it works | Notes |

|---|---|---|---|

| High-mix VMC (quick-change vise) | Standard 52mm/96mm grid aligned to the vise base; keep air ports accessible | Fast swaps without indicating; consistent work offset repeatability run-to-run | Add a simple cleaning routine (blow-off + wipe) before every load |

| HMC tombstone (multi-face) | Wider module spread; symmetrical placement under the tombstone footprint | Improves rigidity for heavy cuts and multi-side machining | Plan for coolant/chip flow so locating faces stay clean |

| 5-axis fixture (low Z-height) | Low-profile plate + compact fixture base; modules positioned for tool clearance | Maintains reach and avoids collisions on trunnion/tilting setups | Prioritize stiffness and access for probing & in-process checks |

| Pallet pool / robot loading | Standardize one pallet pattern + fixed orientation; quick couplers/manifold routing | Reduces mix-ups and stabilizes automation reliability over long runs | Label pallets and lock down datum strategy across machines |

| CNC → CMM transfer pallet | Mirror the plate pattern on the inspection side; keep datum features consistent | Minimizes re-fixturing error and supports true-position verification | Track re-seat variation after cleaning to validate real-world repeatability |

Long-tail keywords: zero-point clamping plate for CNC, 52mm 96mm grid plate, HMC tombstone quick-change base, 5-axis fixture palletization.

Pneumatic requirements & air quality checklist

Most repeatability complaints come from simple basics: inconsistent air pressure, moisture/oil contamination, and chips on locating surfaces. Use this as a practical checklist for pneumatic zero-point workholding (confirm exact values in the catalog for your module).

| Check item | What to aim for | Why it matters |

|---|---|---|

| Stable air pressure | Typical shop air range (often around 5–8 bar) with minimal drop at cycle | Ensures consistent clamping force and repeatable seating |

| Filtration & water separation | Filter + water trap near the machine; keep bowls drained | Prevents seals from swelling, sticking, or leaking over time |

| Dry, clean connections | Avoid coolant mist in couplers; route lines away from chip blast | Reduces contamination that can slow clamp/unclamp response |

| Leak & cycle test | Run repeated open/close cycles after installation or maintenance | Catches small leaks before they become downtime |

| Safety / interlocks | Integrate clamp status to machine/robot logic when applicable | Protects tooling, fixtures, and automation sequences |

Search intent this supports: pneumatic zero-point clamping plate air pressure, zero-point module maintenance, quick-change pallet workholding.

Troubleshooting repeatability & clamping issues

When a plate is used for high-mix CNC machining, tiny issues compound: chips on locating faces, uneven mounting torque, or wet air lines. This table helps you diagnose the most common symptoms quickly.

| Symptom | Likely cause | Quick fix | Preventive habit |

|---|---|---|---|

| Repeatability drifts after chip-heavy jobs | Chips/debris on locating faces or under fixture base | Blow-off + wipe locating surfaces; re-seat and re-check | Add a “clean-before-clamp” step to every changeover |

| Clamp won’t fully lock / inconsistent engagement | Low pressure, small leaks, or contaminated couplers | Verify regulator, fittings, FRL; repeat cycle test | Keep couplers away from coolant mist; drain water trap |

| Fixture rocks / uneven seating | Mounting surface not flat/clean, or torque pattern distorts the plate | Loosen, clean, re-torque in a cross pattern | Use consistent torque tools and a documented mounting procedure |

| Clamp/unclamp feels slow | Moist air or contamination increasing friction in valves/seals | Check filtration, dry air supply, and line routing | Schedule periodic filter maintenance based on coolant/chip environment |

| Audible air leak | Seal wear or damaged fittings | Inspect seals and connections; replace worn consumables | Log cycles and service intervals for critical production cells |

Long-tail keywords: zero-point clamping plate repeatability, workholding pallet troubleshooting, air leak zero-point module, re-seat variation CNC.

Typical tolerance workflow (CNC → CMM → CNC)

A zero-point clamping plate shines when it becomes your standardized datum interface — letting a part stay on the same pallet/fixture from machining to inspection and back again. This reduces re-fixturing error and makes repeatability a measurable capability.

- Lock the datum strategy early: Define A/B/C datums (or a probing datum scheme) and keep it consistent across CNC programs and inspection routines.

- Machine on the pallet: Rough + finish while referencing the same locating features. Record offsets and any in-process probe results.

- Inspect on CMM without re-fixturing: Move the pallet/fixture to CMM and verify critical features, true position, and flatness — aligned to the same datum set.

- Feed results back to CNC: Update wear offsets or apply controlled corrections for the next cycle. Repeat the same locating sequence to confirm stability.

- Document capability: Track clamping repeatability, offset drift, and re-seat variation (especially after chip-heavy operations).

| What to capture | Why it matters |

|---|---|

| Probe/CMM alignment notes | Ensures a consistent CNC → CMM datum transfer workflow |

| Offset history (wear + correction) | Shows stability and helps reduce scrap on repeat jobs |

| Re-seat variation after cleaning | Validates zero-point clamping plate repeatability in real conditions |

Common CMM / inspection features to verify (GD&T)

When the part stays on the same pallet/fixture, you can monitor GD&T trends across runs, catch drift early, and reduce re-fixturing risk.

- True position for holes, dowels, and bolt patterns

- Flatness of reference faces / sealing surfaces

- Perpendicularity between critical faces and bores

- Parallelism for mating surfaces and stack-ups

- Concentricity / coaxial alignment for bores

- Surface profile on complex or sculpted areas

- Runout (circular / total) on rotating features

- Re-seat variation after cleaning and re-clamping

Long-tail keywords: GD&T true position tolerance, CMM pallet inspection, datum transfer, re-clamp repeatability, work offset repeatability.

Common search terms this workflow supports: CMM pallet inspection, datum transfer, work offset repeatability, zero-point clamping plate repeatability, and re-fixturing error reduction.

See It In Action

Rapid Pneumatic Clamping Action

Experience the satisfying speed and power of our pneumatic zero-point clamping. With the press of a button, the system engages with immense force and perfect repeatability, locking the fixture securely. This is the core of our quick-change technology, engineered for reliability in the most demanding CNC production environments.

Compatibility with Self-Centering Vise: Over 90% Setup Time Cut

A key advantage of the manual zero point plate is its perfect compatibility with self-centering vises, which reduces workpiece setup time by over 90%. Traditional setups need repeated manual alignment, which is time-consuming and error-prone, harming part quality. When paired with a self-centering vise, the plate uses pre-set zero references and auto-centering, letting operators fix workpieces in seconds. This is vital for high-mix, low-volume production with frequent job changes, as it increases machine utilization and output while maintaining precision.

Versatile for Vertical/Horizontal MCs & 3/4/5-Axis Systems

The manual zero point plate is highly versatile, fitting vertical/horizontal machining centers (VMCs/HMCs) and 3-axis, 4-axis, 5-axis CNC systems. In vertical machining, it stabilizes workpieces for milling, drilling, and tapping. In horizontal setups, it uses gravity to support longer/heavier workpieces. For complex 4/5-axis tasks like contouring, its precise alignment ensures quality. It serves industries like automotive, aerospace, and medical device manufacturing, eliminating the need for multiple specialized tools, reducing costs, and simplifying inventory management.

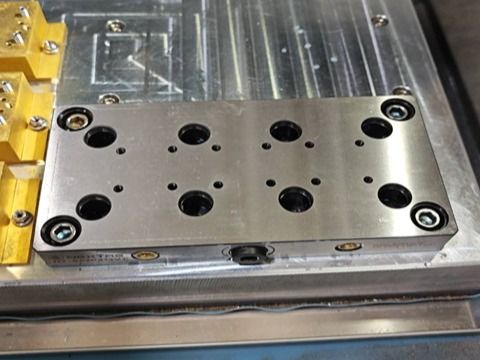

Horizontal Machining Centers (HMCs)

Use clamping plates as the base for tombstone fixtures, allowing you to prepare and load an entire multi-part setup offline and swap it into the machine in minutes.

Vertical Machining Centers (VMCs)

Equip your VMC with a clamping plate to rapidly switch between different vises, 4th-axis rotary tables, or custom job-specific fixtures without lengthy re-alignment procedures.

Automated Pallet Pools

Our clamping plates are the ideal foundation for automated pallet systems. Their robustness and standard interface ensure reliable, repeatable exchanges by robotic loaders 24/7.

CMM & Inspection

Transfer a workpiece directly from the CNC to the CMM on the same pallet, using an identical clamping plate as the reference. This eliminates re-fixturing errors and ensures consistent measurement.

Case Study

Frequently Asked Questions

01 How does a zero-point plate reduce setup time vs. traditional T-slots?

02 What is the typical repeatability I can expect from this clamping plate?

03 What's the difference between a steel and an aluminum clamping plate?

04 What maintenance is required for the integrated pneumatic modules?

05 Can I use this plate for inspection on a CMM as well?

06 Are these plates compatible with my existing self-centering vises?

07 What repeatability can I expect from a zero-point clamping plate?

08 Do I need special air requirements for pneumatic clamping?

09 How do I prevent chips from affecting accuracy?

10 Can I use the plate for 4th-axis / 5-axis fixtures and CMM transfer?

Resources & Downloads

Product Data & Evaluation Checklist

A clamping plate is your foundation—buyers should validate flatness, hardness, stud pattern, and real setup gains.

Key specifications

| Plate role | Universal base plate for repeatable quick-change setups |

|---|---|

| Interface | Receiver layout to match your zero-point standard |

| Reference face | Precision ground surface for stable datum transfer |

| Clamping action | Manual / pneumatic options (model dependent) |

| Mounting | Through holes / threaded patterns (varies by size) |

| Customization | Stud pattern, port orientation, and size can be customized |

Tip: share your part material, machine model, and target takt time. We’ll propose the right configuration and measurable targets.

Compatibility & standards

- Pairs with zero-point receivers and pull studs across your shop standard.

- Works with vises, dovetail fixtures, chucks, tombstones, and custom plates.

- Designed for repeatability when removing/reinstalling fixtures across machines.

Measured outcomes (before → after)

- Changeover time reduction: eliminate repeated re-indicating between jobs.

- More spindle uptime: more cutting time, less setup downtime.

- Better consistency across shifts: standardized mounting reduces variation.

Workholding configuration

- Define pattern: receiver positions, stud locations, and tool clearance.

- Datum plan: how the plate references machine table/pallet and part datums.

- Access planning: ensure 5-side reach, chip evacuation, and coolant flow.

Evidence & proof

- Plate drawing with receiver pattern and flatness requirements.

- On-table photos showing fixture swap and repeat setup.

- Verification checklist: flatness, parallelism, and re-clamp repeat tests.

Delivery & support

- Standard sizes available; custom patterns supported for OEM fixtures.

- Packing options: protective carton / wooden case for heavy plates.

- After-sales: pattern expansion guidance and spare stud/receiver planning.

Related Products

Zero-Point Systems

The core clamping modules that provide the locking force and precision.

View Details →

Pneumatic Vise

Ideal for automated production lines, offering fast and stable clamping.

View Details →

R-Series Chuck

High-precision pneumatic chuck for stationary and rotary applications.

View Details →