Our Product Portfolio

Engineered for precision, speed, and reliability. Explore our comprehensive range of workholding solutions designed to maximize your machining efficiency.

All Products

Self Centering Vise

Zero Point Clamping Plate

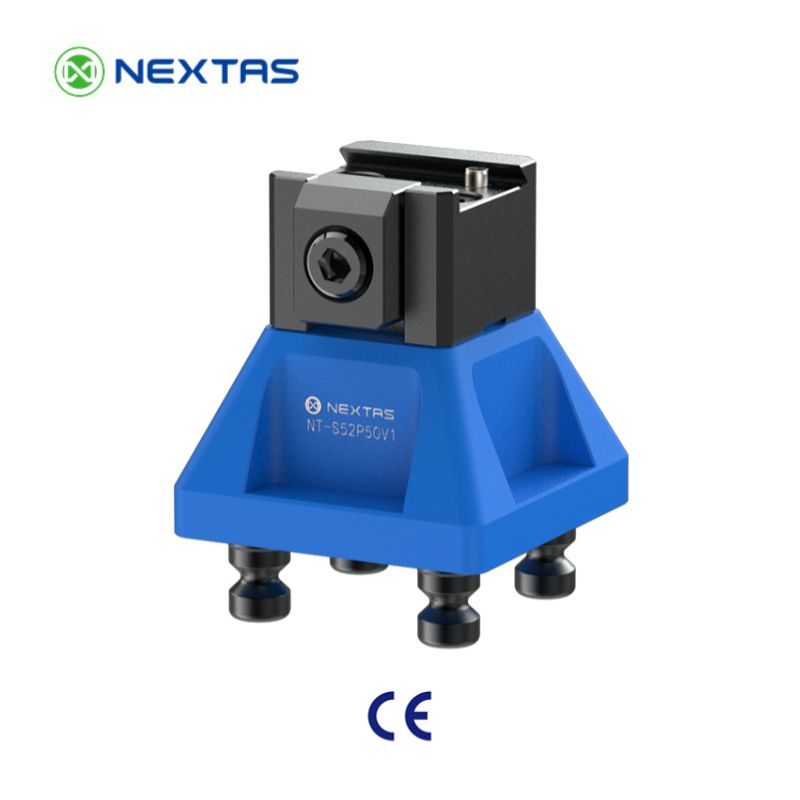

Zero Point Clamping System

Pneumatic Vise

Dovetail Fixture

Rapid Prototyping

E-Series Chuck

R-Series Chuck

Pneumatic Zero Point Plate

Automatic Pallet Changer

Customized Hydraulic Fixture

Choosing the Right Workholding for Your CNC Process

Not sure where to start? Use this quick guide to match the best workholding to your parts, machines, and production goals.

High‑Mix / Quick Changeovers

Zero‑point clamping plates and systems reduce setup time and help you standardize pallets, fixtures, and 5‑axis work.

Automation & Robotics

Pneumatic vises, pneumatic zero‑point plates, and pallet changers enable consistent clamping for unattended production.

5‑Axis & Complex Parts

Dovetail fixtures and self‑centering vises maximize tool access while keeping rigidity and repeatability on thin‑wall parts.

Typical Selection Checklist

| Repeatability | Look for stable, repeatable location (e.g., zero‑point repeatability up to ±0.002 mm on supported setups). |

|---|---|

| Clamping force & stroke | Choose the right force/stroke for your material and cutting parameters to prevent vibration and part lift. |

| Interface & compatibility | Verify pallet size, bolt pattern, locating pins, and machine table interface. |

| Workpiece access | Prioritize low‑profile clamping for 5‑side machining and short tools. |

| Environment | Consider coolant, chips, corrosion resistance, and maintenance intervals. |

Quality, Traceability & Engineering Support

Customers choose NextasTech for predictable results on the shop floor—repeatable setups, durable components, and responsive technical support.

-

Manufacturing know‑how since 2009

Process-focused production to support precision workholding at scale.

-

Documented inspection & consistency

Incoming material checks, in‑process inspections, and final QC for stable performance.

-

Surface protection options

Wear‑resistant finishes and corrosion protection suited to coolant environments.

-

Application engineering

Share your part drawing and machine model—our team can recommend a standard solution or design a custom fixture.

Industries & Typical Use Cases

Our workholding is widely used for precision milling and automation projects across multiple industries.

- •Aerospace components and structural parts

- •Automotive powertrain and aluminum housings

- •Medical devices and precision instruments

- •Mold & die / EDM prep operations

- •General job shops with high-mix production

Need drawings, recommendations, or a quotation?

Send us your part size, material, machining operations, and target cycle time. We'll reply with a suggested configuration and lead time.

Need a Custom Workholding Solution?

If our standard products don't meet your exact needs, our engineering team can design and build a bespoke fixture tailored to your specific part, machine, and process.

Why Choose NextasTech for CNC Machine Accessories?

Your trusted partner in precision engineering and manufacturing efficiency.

Unmatched Precision

Our products are manufactured to the highest standards, ensuring exceptional accuracy and repeatability for all your machining needs.

Enhanced Durability

Built with robust materials and superior engineering, our accessories are designed for long-lasting performance even in demanding environments.

Productivity Boost

Our quick-change systems and efficient workholding solutions drastically reduce setup times and maximize machine uptime.

Expert Support

Our dedicated team provides professional technical support and custom solutions to meet your unique manufacturing challenges.

Frequently Asked Questions (FAQ)

How does your Self-Centering Vise ensure accuracy?

Our self-centering vises use a high-precision ground leadscrew and an adjustable backlash-free nut design. This not only ensures a centering repeatability of ±0.005mm from the factory but also allows you to compensate for wear after long-term use, restoring its original high accuracy and extending the vise's service life.

What is the main advantage of a Zero-Point System?

The biggest advantage of a zero-point system is the drastic reduction in workpiece changeover time—by up to 90%. It allows you to preset workpieces off-machine and then lock them onto the machine in seconds with high precision (repeatability of ±0.002mm). This significantly increases machine uptime and production flexibility.

When should I choose a Pneumatic Vise?

Pneumatic vises are ideal for automated production lines and repetitive tasks requiring fast, consistent clamping force. If you are using robotic loading/unloading or want operators to load parts quickly with the push of a button, a pneumatic vise is the perfect choice. Its constant clamping force also helps ensure process stability.

What type of machining is your Dovetail Fixture suitable for?

Dovetail fixtures are an excellent choice for 5-axis machining. They require only a small dovetail prep (e.g., 3mm) on the raw material to provide exceptional clamping force. This low-profile clamping allows maximum tool access to five sides of the workpiece, making it perfect for complex, thin-walled parts or monolithic components.