Enter your email address to request the brochure. Due to time zone differences, we’ll email it the next business morning (GMT+8, Beijing Time).

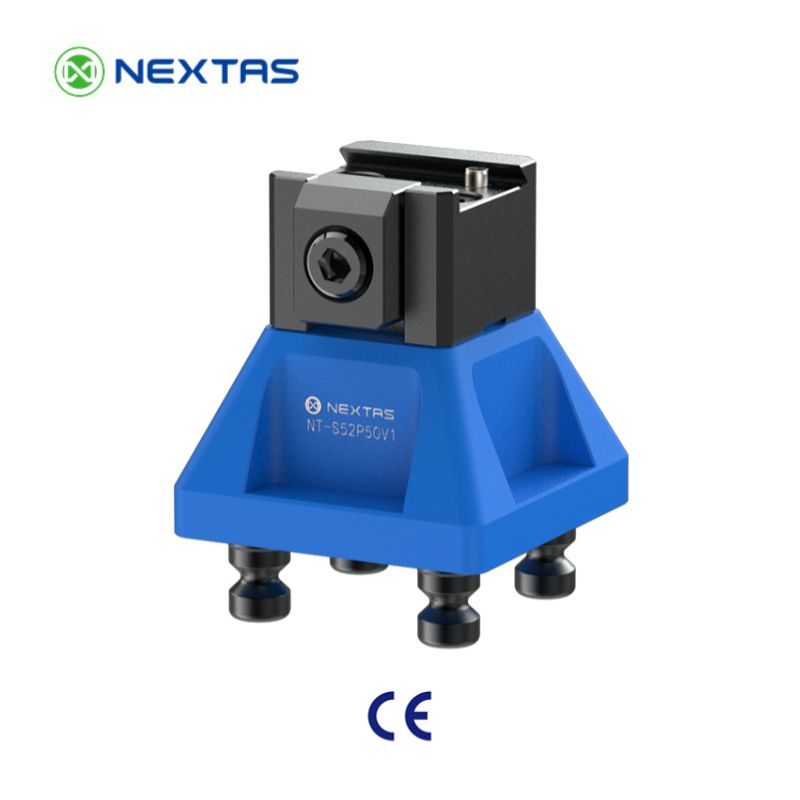

Modular Dovetail Fixture

Rigid 5-Side Clamping for 52 & 96 Systems

Engineered for high-speed five-axis machining, the NextasTech dovetail fixture securely grips the workpiece on a small 45° profile, exposing five faces for machining while minimizing material waste. Precision locating pins ensure repeatable positioning, and the modular 52 / 96 mm base integrates seamlessly with zero-point plates and quick-change systems for lightning-fast setups.

Core Advantages

- Five-Side Machining Access: Grips stock on a minimal 45° dovetail profile to expose five faces for machining, allowing more part to be milled per setup and reducing material waste.

- Superior Clamping Force: The 45° dovetail design produces high clamping force and rigid stability, resisting cutting vibrations and preventing slippage.

- High Precision & Repeatability: Precision locating pins and ground surfaces ensure repeatable positioning and eliminate workpiece movement.

- Modular 52 / 96 Integration: Standard 52 mm and 96 mm patterns integrate with zero-point systems and quick-change plates for flexible mounting and rapid changeovers.

- Lightweight & Durable: Aerospace-grade aluminium body with stainless steel inserts provides high strength, reduced weight and long-term stability.

- Versatile & Automation Ready: Supports a wide range of materials and is ideal for high-mix production and robotic automation thanks to quick setups and a compact footprint.

Technical Specifications

Both 52 mm and 96 mm dovetail fixtures conform to industry-standard zero-point mounting patterns. Detailed dimensional drawings are provided below for quick reference.

Five-Side Machining Efficiency

The dovetail fixture clamps the workpiece along a small 45° dovetail, leaving the top, front, back and two sides completely unobstructed for cutting. This design enables true five-side machining in a single setup and reduces the extra material normally required for gripping, saving both time and raw material costs.

Precision & Repeatability

Each dovetail fixture is fitted with precision locating pins and ground reference surfaces to eliminate slide and ensure high repeatability when swapping parts. Combined with the rigid dovetail geometry, this guarantees consistent machining accuracy and surface finish.

- Patented design for small plate processing on 3/4/5-axis machines.

- Adjustable clamping position with selectable pressing plates.

- Support column with scale adjustment for precise hold-down placement.

- Side U-shaped groove avoids tool interference during side machining.

- Optional 3R or Erowa spigot positioning interfaces.

Modular & Zero-Point Compatible

The base of the fixture is machined to industry-standard 52 mm and 96 mm patterns, making it directly compatible with zero-point clamping plates, quick-change systems and automation pallets. This modularity streamlines setup changes and allows multiple fixtures to be mounted in high-density arrays for increased throughput.

Applications & Use Cases

Case Study: Industrial Automation

The dovetail fixture pairs seamlessly with the pneumatic zero-point plate, enabling fast, precise clamping of thin-sheet products in industrial automation. It slashes setup time, ensures stable machining, and boosts machining efficiency by over 30%.

Complex 5-Axis Machining

Ideal for titanium and aerospace parts requiring full-surface access. The dovetail fixture exposes five faces, allowing intricate features to be milled in one setup without repositioning.

Quick Change & Automation

With standard 52 / 96 mm mounting patterns, fixtures drop into zero-point plates for lightning-fast swaps. Combine with robotic pallet changers for fully automated, high-density production lines.

Material Versatility

From aluminium to hardened steel, the dovetail fixture securely holds a variety of materials. Its balanced design reduces distortion and makes it perfect for prototyping as well as series production.

System Selection & Zero‑Point Integration Guide

Plan dovetail workholding like a system: fixture size, zero‑point base, pallet/automation strategy, and chip/coolant flow all affect real‑world repeatability.

System 52 vs System 96: quick decision table

Use this decision matrix when you’re choosing a 45° dovetail fixture for 5‑axis machining and a zero‑point clamping stack. It’s a fast way to align part size, cutting load, and automation needs.

| Consideration | System 52 | System 96 | What to verify |

|---|---|---|---|

| Part size & handling | Small to mid-size parts; higher station density on a compact plate. | Mid to larger parts; more base area for stable docking on pallets. | Machine envelope, pallet size, and how you load (manual/robot). |

| Cutting load & rigidity | Great for general milling and lighter roughing; optimize toolpaths to keep forces balanced. | Best when you need maximum stiffness for heavier roughing or tougher materials. | Stock removal rate, tool length, chatter risk. |

| Automation / palletization | Lower mass helps robots and quick swaps; ideal for high‑mix cells. | More stable on larger pallets; preferred for lights‑out cells with heavier parts. | Receiver/pallet compatibility and repeatability after swaps. |

| Chip & coolant clearance | Compact layouts can pack stations tightly—plan chip evacuation carefully. | More spacing options for shields, air blast, and chip evacuation. | Coolant direction, chip buildup risk, cleaning routine. |

| Typical use cases | Prototype → production, small housings, thin‑wall/window‑style parts, high-density arrays. | Larger brackets, tougher alloys, higher torque cuts, palletized production. | Target tolerance, surface finish, and cycle time goals. |

Tip: If you’re building a palletized cell, pair the fixture with a zero‑point plate so stations can be exchanged without re‑indicating.

When to choose System 52

Best for small to mid‑size parts, tight machine envelopes, and high‑density arrays. Great for quick prototype-to-production changeovers on 3‑axis/4‑axis/5‑axis machines.

- High station density on a compact plate

- Fast swapping on System 52 zero‑point receivers

- Lower mass for rapid robot handling

When to choose System 96

Use System 96 for heavier cuts, larger parts, or when you need maximum rigidity on pallets and automation cells.

- Wider base improves stability

- Pairs well with larger zero‑point plates/pallets

- More room for stops, locators, and chip evacuation

Automation & palletization tips

For lights‑out production, combine a dovetail fixture with a zero‑point plate and pallet changer so stations can be exchanged without re-indicating.

- Pair with a pneumatic zero‑point plate for fast, repeatable docking

- Scale with an automatic pallet changer for unattended changeovers

- Use multiple fixtures per pallet to increase spindle uptime and reduce WIP

Dovetail Prep & Best Practices for 5‑Side Machining

A clean, consistent 45° dovetail is the difference between “it holds” and “it runs production.” These steps help you get stable clamping and predictable cycle times.

1. Machine a consistent 45° profile

Use a matching dovetail cutter and keep the depth consistent across batches. Deburr the profile so the fixture seats fully.

2. Control part distortion

Clamp close to stiff regions. For thin or window‑style parts, use support columns/pressing plates to avoid bending.

3. Validate with a trial cut

Run a short rough+finish program, then check key datums. If needed, add stops/locators to prevent axial slip.

4. Keep interfaces clean

Chip contamination is the #1 enemy of repeatability—clean the dovetail and the zero‑point interface before every swap.

Next step

Share your part size, material, and machine model. We’ll propose a proven 45° dovetail workholding setup (fixture size, station layout, and zero‑point stack) to match your tolerance and takt time.

Troubleshooting: keep your dovetail workholding repeatable

Even a great 45° dovetail fixture can lose repeatability if chips, distortion, or excessive tool load creep in. Use this quick table to diagnose the most common issues in 5‑axis dovetail workholding and zero‑point setups.

| Symptom | Likely cause | Recommended fix |

|---|---|---|

| Part slips during roughing | Dovetail profile inconsistent, clamp not seated, or cutting forces too aggressive. | Re‑cut the 45° profile, deburr, and reduce tool engagement; add stops/locators if needed. |

| Chatter / vibration marks | Insufficient rigidity, long tool reach, or resonance at high RPM. | Switch to System 96 or reduce overhang; tune feeds/speeds; use shorter tools and balanced toolpaths. |

| Thin walls distort | Clamping near flexible regions or uneven support on window‑style parts. | Clamp closer to stiff ribs; use support columns/pressing plates; verify distortion after a trial cut. |

| Z height shifts after swapping | Chips on the dovetail or on the zero‑point interface; coolant film. | Clean both interfaces every swap; add air blast/brush at load station; keep receivers dry and protected. |

| Marks on the dovetail | Burrs, too much clamping pressure, or poor surface condition. | Deburr and add a small lead‑in chamfer; use correct clamp force; consider sacrificial dovetail pads. |

| Repeatability degrades over time | Wear, contamination, or damaged locator pins. | Inspect pins and contact surfaces; replace worn inserts; schedule periodic cleaning and calibration checks. |

If you’re running lights‑out production, pair this fixture with a pneumatic zero‑point plate and pallet changer so docking is consistent across stations.

Dovetail Fixture Selection Checklist

Validate fit, rigidity, and automation readiness before you commit to a production workholding stack.

Part & process

- Material (aluminum / steel / titanium) and target removal rate

- Part geometry: thin wall, window style, or tall features

- Target tolerance and whether you want to avoid re-indicating

System compatibility

- System 52 vs System 96 decision based on load and density

- Zero‑point base / pallet interface (receiver pattern, clearance)

- Automation plan: robot handling, pallet changer, queue length

Dovetail prep

- 45° dovetail depth and width (repeatable across batches)

- Deburring and seating check (no chips at contact faces)

- Stops/locators if heavy torque or aggressive side milling

Proof & support

- On‑machine photos/videos showing tool clearance

- Inspection excerpt for multi‑face positional results

- Spare parts plan for screws/pins and recommended maintenance

Frequently Asked Questions

How much material do I need to prepare for the 45° dovetail?

What is the primary difference between the 52 mm and 96 mm dovetail fixtures?

Can I use these dovetail fixtures on a 3-axis or 4-axis machine?

What dovetail angle and cutter do you recommend?

How does this dovetail fixture compare to a self-centering vise for 5-side machining?

How do I prevent part pull-out or vibration during aggressive machining?

Is it suitable for thin plates or window-style parts?

How repeatable is swapping parts when combined with a zero-point plate or pallet?

What kind of maintenance do these fixtures require?

Are the clamping components and locating pins replaceable?

Resources & Downloads

Related Products

E-Series Chuck

A versatile and precise chuck for a wide range of automated turning applications.

View Details →R-Series Chuck

Provides powerful, consistent clamping for heavy-duty turning and milling operations.

View Details →Automatic Pallet Changer

Drastically reduce setup time and increase machine uptime with fully automated pallet changes.

View Details →