Enter your email address to request the brochure. Due to time zone differences, we’ll email it the next business morning (GMT+8, Beijing Time).

E-Series Automation Chuck

Precision for Automated Manufacturing

The NextasTech E-Series Chuck is the definitive solution for high-precision, automated manufacturing. Fully compatible with the EROWA ITS system, this chuck provides a universal interface for electrodes and workpieces across various processes like EDM, milling, and grinding. Its robust design and exceptional repeatability make it the cornerstone of any modern, flexible production environment.

Product Details

The NextasTech E-Series Chuck operates on a proven principle of precision and reliability. The chuck's internal mechanism, actuated by compressed air, opens the clamping collet to accept a workpiece holder or electrode. When the air is released, the collet closes with immense force, pulling the holder into a precise, repeatable Z-position against the hardened contact surface. This system not only ensures accuracy but also allows for rapid, automated changes, forming the backbone of a "set up once, machine anywhere" production philosophy.

Built for Durability and Automation

Manufactured from high-grade, rust-proof stainless steel, the E-Series Chuck is engineered to withstand the demanding conditions of EDM and grinding operations. Its sealed design prevents ingress of dielectric fluid and abrasive particles. Integrated connections for air pressure, cleaning, and presence check functions allow for seamless communication with robotic handlers and machine controllers, making it a truly "plug-and-play" component for any automation cell.

Technical Specifications

| Parameter | Specification (Model Example: NEX-C100) |

|---|---|

| Compatibility | EROWA ITS Chucks (ER-036345, etc.) |

| Repeatability | ≤0.002 mm |

| Clamping Power | 6000 N |

| Actuation | Pneumatic, single-acting |

| Operating Pressure | 6 ± 1 bar |

| Connections | Rear or side air connections |

| Body Material | Stainless Steel, rust-resistant |

| Weight | 3.5 kg |

System Selection & EROWA ITS Integration Guide

If you’re building an EDM electrode workflow or a palletized cell, the E‑Series Chuck becomes the “reference hub”: set up once, then move holders between machines with predictable Z and minimal touch‑off.

Pick the right holder strategy

- 100% compatible with EROWA ITS holders and pallets (ITS 50 / ER‑036345 family).

- Ideal for sinker EDM electrodes, wire‑EDM pallet pools, grinding, and CMM inspection where Z repeatability matters.

- Standardize pull‑studs and a master holder to reduce height variation across machines.

Design for unattended automation

- Air release + spring clamp means the chuck stays locked if air pressure drops (failsafe clamping).

- Add clamp confirmation (sensor or pressure interlock) so robots only move when fully clamped.

- Use the integrated air‑blast port to clear dielectric/coolant film and chips before every clamp.

Workflow‑based configuration quick guide

| Workflow / process | Recommended holder & accessories | Why it works | Notes |

|---|---|---|---|

| Sinker EDM electrode machining | ITS electrode holder + master holder for verification | Fast swaps with consistent Z; reduces re‑touch‑off | Run an air‑blast purge before clamping in heavy graphite sludge |

| Wire EDM pallet pool | ITS pallet / work carrier + clamp confirmation | Stable reference for unattended pallet changes | Use a simple OK/NG signal to the robot/APC |

| Grinding / jig grinding | Short, rigid holder + clean reference routine | Minimizes stack‑up error and vibration sensitivity | Prioritize clean, dry air and frequent face wipe |

| High‑speed milling of electrodes | Balanced holder + protective air blast | Helps maintain repeatability under frequent changes | Consider guarding against coolant mist ingress |

| CMM / inspection stations | Master holder + fixed datum workflow | Quick cross‑machine verification of Z datum | Document the master holder ID in your quality plan |

Automation ports, signals & best practices

| Automation element | Typical connection | Purpose | Best practice |

|---|---|---|---|

| Air release | 6 ± 1 bar clean/dry air | Opens the clamp for loading/unloading | Keep hoses short; use a 5 µm filter (or better) |

| Air‑blast cleaning | Timed air pulse (valve / PLC) | Clears chips and dielectric/coolant film on the interface | Pulse before every clamp to protect repeatability |

| Clamp confirmation | Pressure switch or proximity sensor | Prevents robot motion until fully clamped | Use a dual‑check (pressure + sensor) for 24/7 cells |

| Presence / seating check | Machine input (I/O) / interlock | Detects missing holder or incomplete seating | Stop the cycle if seating is not confirmed |

| Maintenance counter | PLC counter / MES | Service planning for seals/springs | Trigger inspection by cycles (not only calendar time) |

Long‑tail keywords: E‑series automation chuck for EDM electrodes, EROWA ITS 50 compatible pneumatic chuck, spring‑clamp air‑release workholding, palletized EDM workholding for robots, 2 micron repeatability chuck, stainless steel EDM chuck with air‑blast cleaning.

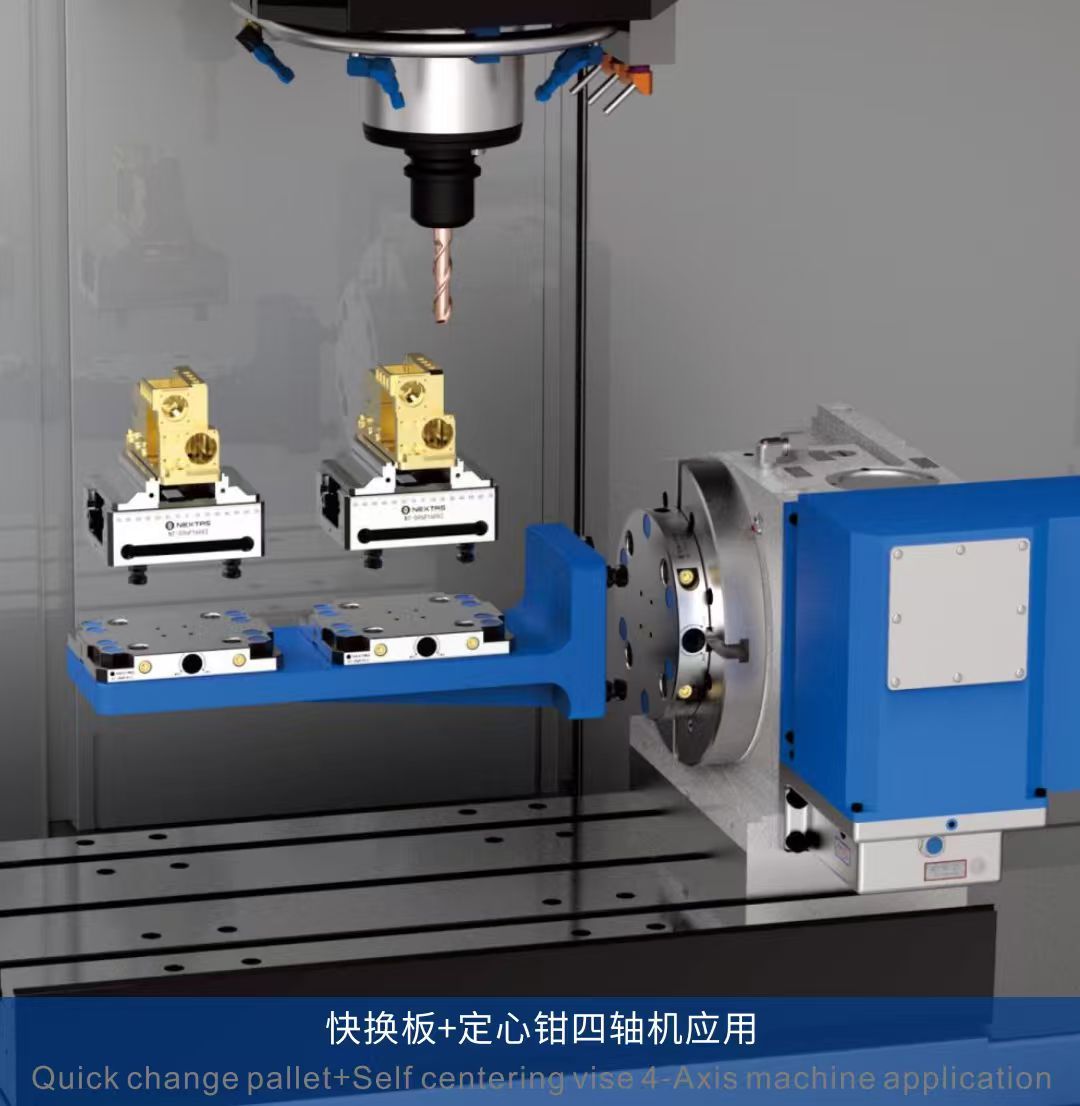

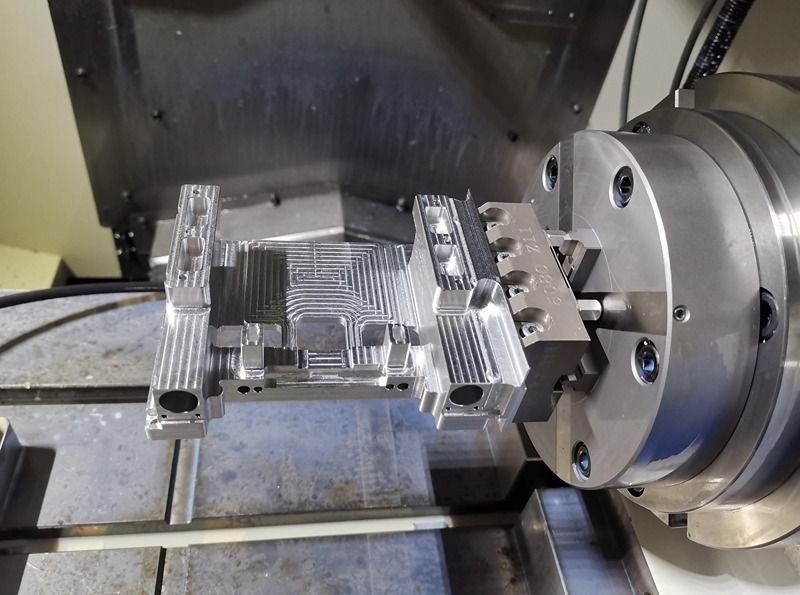

Application Cases

EDM (Electrical Discharge Machining)

The corrosion-resistant construction and high precision make it the industry standard for holding electrodes and workpieces in die-sinking and wire-cut EDM machines.

High-Speed Milling

Provides a rigid, stable base for high-speed milling operations. Workpieces can be pre-set offline on pallets and quickly loaded into the machine, maximizing spindle uptime.

Grinding & Jig Grinding

The exceptional repeatability is critical for precision grinding operations, ensuring ultimate accuracy for tight tolerances and fine surface finishes.

Tool & Mold Making

The ability to move a workpiece between different technologies on the same holder is a game-changer, drastically reducing lead times and improving accuracy.

Pneumatics, Setup & Maintenance for Unattended EDM

Repeatability in automation is a system outcome: clean air, clean reference faces, and a stable referencing routine. Use the checklist below to keep 2‑micron‑level performance predictable over thousands of cycles.

Recommended air supply

- 6 ± 1 bar clean, dry compressed air.

- Add a 5 μm filter (or better) and drain/air dryer to prevent sticky sludge in valves and seals.

- Use short air lines and quick couplers to reduce cycle time and pressure drop.

Setup & verification

- Bolt to a flat, stress‑free adapter plate; verify flatness before final torque.

- Run 20–50 clamp/unclamp cycles, then re‑check Z reference to confirm stability.

- Document a master gauge/holder so every machine can verify the same datum quickly.

Maintenance & reliability

- Wipe reference surfaces daily in EDM (dielectric + graphite dust can drift Z).

- Use the built‑in air blast before every clamp to clear chips/fluid from tapers and receivers.

- Inspect seals/springs at planned intervals and keep a spare seal kit for 24/7 cells.

Tip for robot cells: add clamp confirmation + air‑pressure monitoring to your PLC interlock so the robot only departs when the chuck is fully locked.

Real-World Case Studies

Frequently Asked Questions

What is the repeatability of the E‑Series Chuck, and how is it verified?

Repeatability is ≤0.002 mm (2 μm). Each unit is verified with certified CMM measurement before shipment for documented consistency.

How does the clamping mechanism work—air‑release or air‑clamp—and what is the force?

It is air‑release (single‑acting pneumatic). Air opens the collet; releasing air engages springs that clamp with 6,000 N, keeping the holder locked even during air loss.

Is it fully compatible with EROWA ITS holders and pallets (ITS 50 / ER‑036345)?

Yes. The E‑Series is designed for full EROWA ITS compatibility, so you can use existing ITS holders, electrodes, and pallets without modification.

Which processes is it best suited for?

It’s ideal for die‑sinking EDM, wire EDM palletization, electrode machining, grinding, and inspection where repeatable Z referencing is critical.

How does it handle chips, dielectric fluid, and debris in automation?

Integrated air‑blast ports purge the mating surfaces during unclamp. In heavy EDM sludge, add routine wipe/purge cycles to keep reference faces clean.

What air supply quality is recommended for stable unattended cycles?

Use clean, dry air at 6 ± 1 bar with filtration (≈5 μm) and drainage/air drying to protect seals and maintain consistent actuation.

How do I maintain the same Z reference across multiple machines?

Standardize the same ITS holders and keep a master gauge/holder. Touch off once, then verify the datum periodically using the master for quick cross‑machine checks.

Can it be integrated with robots or pallet systems safely?

Yes—pair it with clamp/unclamp confirmation (sensor or air‑pressure interlock) so the robot only moves when the chuck is fully locked.

What should I check when retrofitting onto an existing table or adapter plate?

Confirm mounting flatness and rigidity, avoid distortion from uneven torque, and verify repeatability after 20–50 cycles before running production.

What maintenance routine is typical for EDM environments?

Clean reference faces regularly, use air blast before clamping, and inspect seals/springs on a planned schedule—especially in dielectric + graphite dust conditions.

Resources & Downloads

Validation Checklist & Commissioning Plan

Use this purchase/FAT/SAT checklist to confirm repeatability, clamping reliability and interface cleanliness for unattended EDM automation.

Incoming inspection & acceptance criteria

| Item | How to verify | Typical target |

|---|---|---|

| Repeatability at Z datum | CMM or dial indicator with a master holder; cycle clamp/unclamp 20–50 times | ≤ 0.002 mm (2 µm) on the same reference |

| Clamp force & failsafe behavior | Confirm spring clamp holds with air removed; verify no unintended release | Remains locked without air; stable holding during power/air events |

| Interface seating cleanliness | Visual + wipe test; run air‑blast and inspect contact face | No trapped chips/film; consistent seating marks |

| Pneumatic response time | Measure unclamp/clamp time at 6 ± 1 bar | Stable timing; no lag from pressure drop/leaks |

| Leak & seal health | Soapy‑water leak check; monitor pressure decay | No visible leaks; low decay over hold period |

| ITS compatibility | Test with your standard ITS holders/pallets and pull‑studs | Smooth load/unload; no rocking; consistent Z |

| Documentation | Request verification report + maintenance notes | Traceable QC records for your quality system |

Troubleshooting quick table

| Symptom | Likely cause | Fix |

|---|---|---|

| Z shifts after several cycles | Dirty contact faces or inconsistent air‑blast timing | Add purge before clamp; wipe faces; standardize cleaning interval |

| Holder won’t seat fully | Chips/debris on taper/interface; bent pull‑stud | Clean interface; replace pull‑stud; verify holder condition |

| Slow or incomplete release | Low air pressure, clogged filter, long hoses | Restore 6 ± 1 bar; replace filter; shorten lines |

| Robot moves without solid clamp | No clamp confirmation interlock | Add pressure switch/sensor and gate robot motion by OK signal |

| Rust/contamination risk | Incompatible environment protection | Use stainless + sealed routing; improve coolant/dielectric shielding |

Include in your RFQ: your machine model(s), EDM/coolant environment, holder/pallet standard (ITS 50), expected cycle count, and whether you need clamp confirmation I/O. We’ll recommend ports, valves and a maintenance interval.

Related Products

Explore other solutions that complement the E-Series Chuck and enhance your production line.

R-Series Chuck

A versatile chuck for various machining applications, offering robust clamping and reliability.

View Details

Self Centering Vise

Precisely centers workpieces of various sizes for accurate milling and drilling operations.

View Details

Automatic Pallet Changer

Maximize machine uptime with seamless, automated pallet changes for continuous production.

View DetailsRelated Articles

Gain insights from our experts on how to optimize your manufacturing processes.