Precision Workholding for Peak Performance

Unleash the Full Potential of Your CNC Machines

Contact NextasTechExplore Our Core Products

Slash setup times by up to 90% and achieve micron-level accuracy. Our systems deliver unparalleled repeatability for flawless production.

Zero-Point Clamping Systems

Learn More →

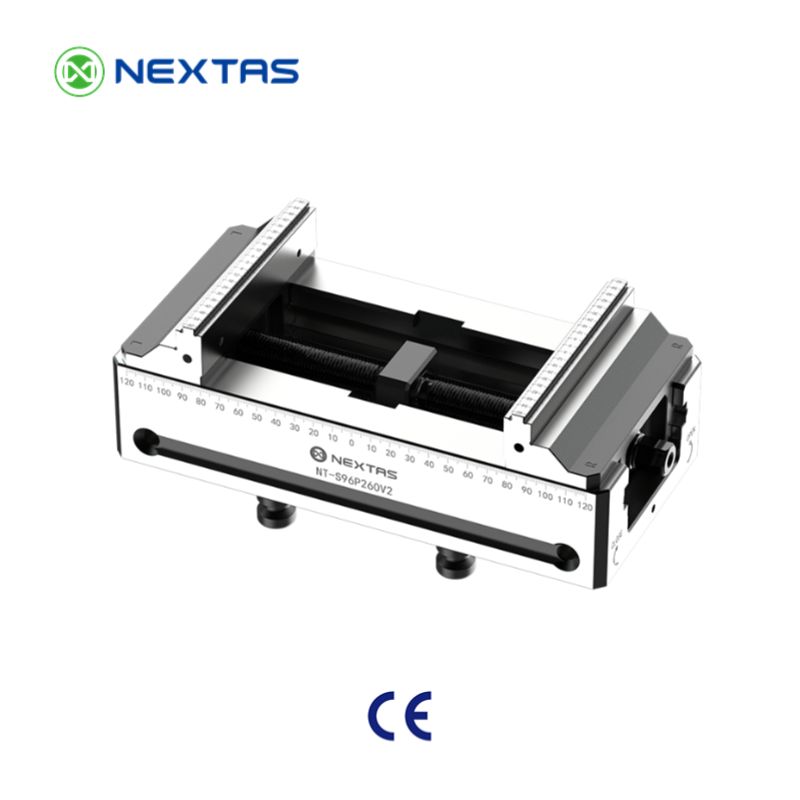

Self Centering Vise

Learn More →

Zero Point Clamping Plate

Learn More →

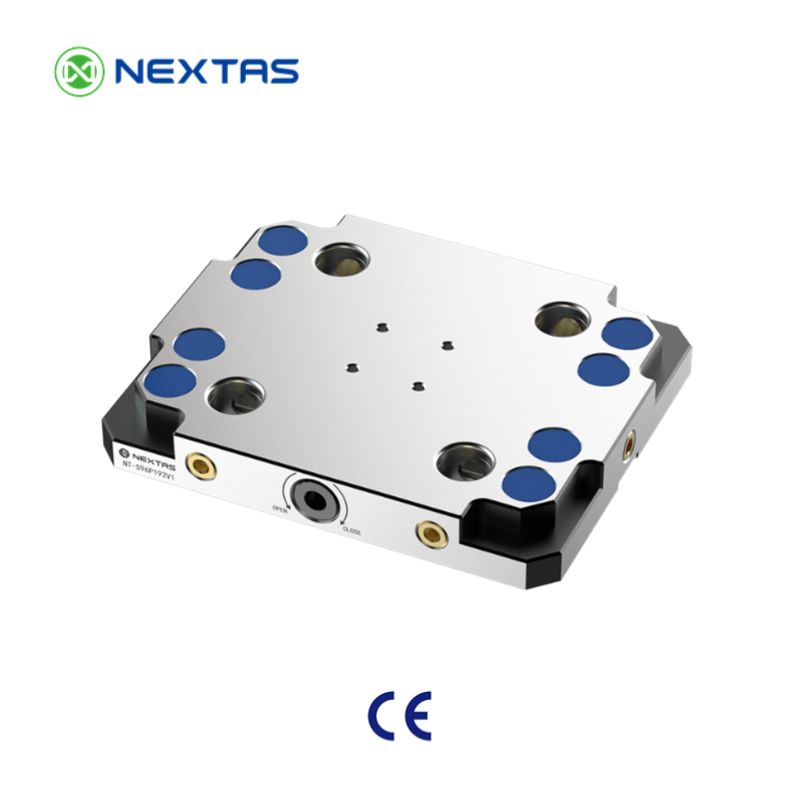

Pneumatic Zero Point Plate

Learn More →

Pneumatic Vise

Learn More →

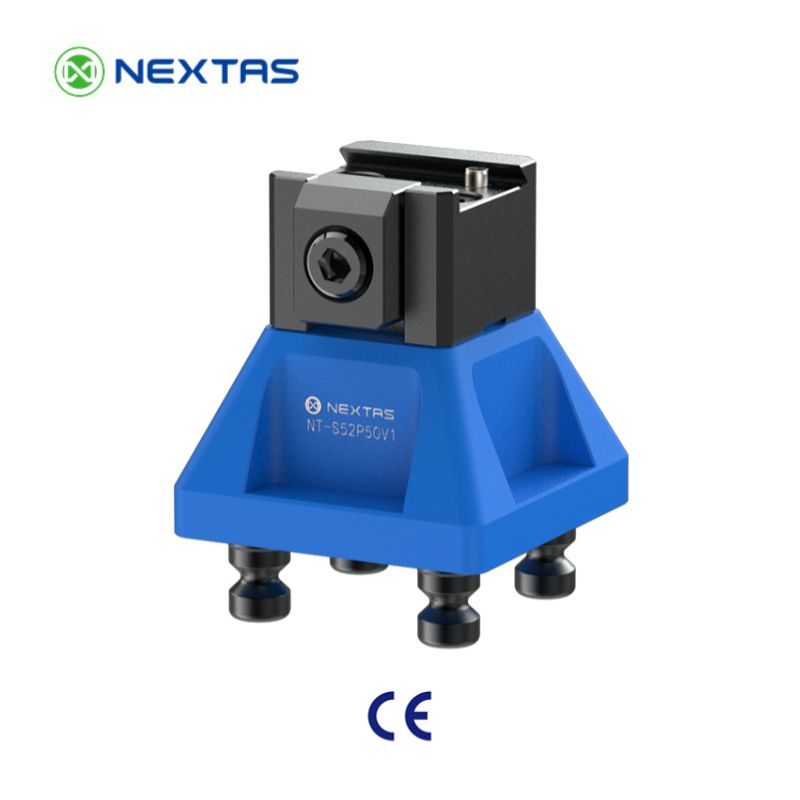

Dovetail Fixture

Learn More →

Rapid Prototyping

Learn More →

Customized Hydraulic Fixture

Learn More →

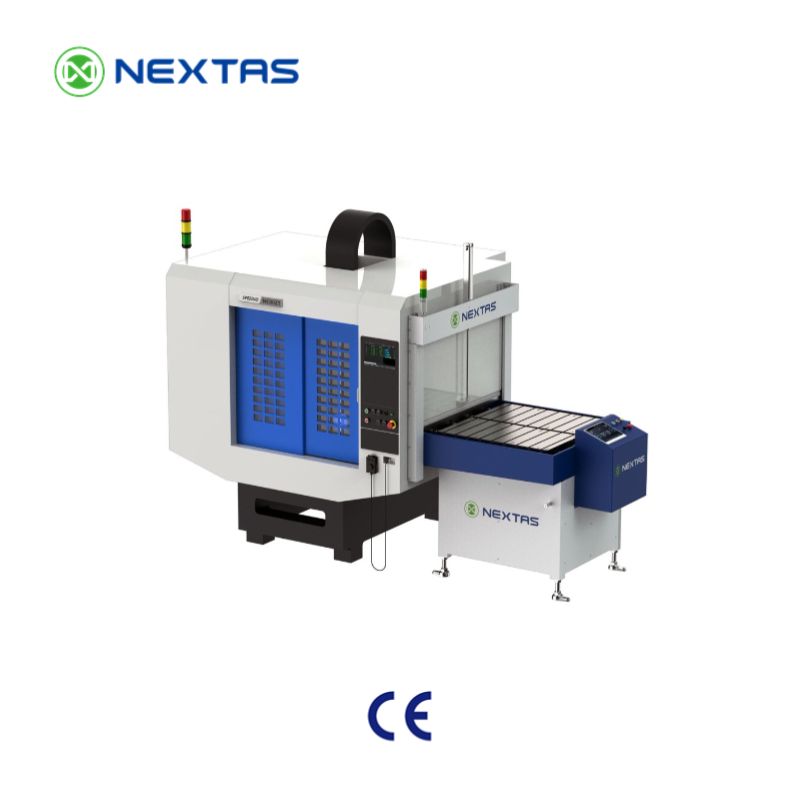

Automatic Pallet Changer

Learn More →Workholding Solutions for 5-Axis CNC, Automation & High-Mix Production

Whether you run a single VMC or a fully automated cell, the right workholding is what turns “good” machining into consistent throughput. NextasTech systems are built for fast changeovers, rigid clamping, and repeatability down to ±0.002 mm—with hardened wear surfaces (HRC 58-62) for long service life.

5-Axis Milling & Full Tool Access

- Low-profile clamping for trunnion tables and 5-side machining

- Dovetail workholding helps reduce distortion on thin-walled parts

- Combine with zero-point receivers for fast, repeatable repositioning

Lights-Out Automation & Robots

- Pneumatic zero-point plates for automated lock / unlock

- Self-cleaning air-blast channels help prevent chip contamination

- Ready for pallet pools, robots, and automated pallet changing

Quick-Change Pallets & Pallet Pools

- Standardize pallets and fixtures to cut changeover time

- Repeatable locating for multi-operation machining across machines

- Great for HMC tombstones, VMC quick-change, and job shops

High-Precision Finishing & Repeatable Offsets

- Repeatability down to ±0.002 mm for stable work offsets and probing

- Rigid clamping helps eliminate micro-vibration for surface finish

- Every unit is verified on CMM equipment before shipment

Thin-Walled & Delicate Parts

- As little as 3 mm dovetail engagement for secure, low-profile clamping

- Clamping direction designed to minimize deformation

- Ideal for aluminum, titanium, and complex geometries

Automotive & High-Volume Fixtures

- Customized hydraulic fixtures for stable, cycle-time-focused production

- Pneumatic clamping and multi-station setups for line efficiency

- Engineering support from concept to production-ready tooling

Not sure what fits your machine? Share your part drawing and machine model—our engineers will recommend a proven setup.

Talk to an EngineerWorkholding Guides, Case Studies & Engineering Notes

Browse practical, shop-floor-oriented articles on zero-point clamping, pallet changing, pneumatics, and automation—written to help you choose the right interface and avoid costly rework.

High-Performance Zero-Point Clamping Plates: Elevate Your Machining Efficiency

When to choose a clamping plate vs. a full receiver system—and what it means for VMC/HMC changeovers.

Read more →Pneumatic Zero‑Point Plates: Enhancing Automation and Quick Change in Manufacturing

How pneumatic lock/unlock supports robotics, pallet pools, and chip-resistant quick change.

Read more →5-Axis Self-Centering Vise: What Makes It Ideal for Complex Machining?

Key geometry and forces that matter for 5-axis machining and complex workpieces.

Read more →Unlock CNC Efficiency: The Magic of Manual Pallet Changer System

A practical guide to reduce setup time without moving straight to full automation.

Read more →FMS for Small-to-Medium Manufacturers (SMMs): Affordable Solutions to Scale Production

How small-to-medium shops can adopt flexible manufacturing systems step-by-step.

Read more →Solving Large Part Machining: NextasTech Side‑Inlet Zero‑Point Clamping System Guide

A compact side-inlet design for large parts and tight Z-axis clearance.

Read more →Zero-Point Clamping Plates: How Material Hardness Ensures Unmatched Longevity

Why alloy steel and heat treatment drive wear resistance and long service life.

Read more →A Must for Unmanned Workshops: The NextasTech Automated Integration Solution

A blueprint for lights-out machining: clamping, pallets, and automation integration.

Read more →NextasTech Zero Point Positioning System: Successful Application at SAVANT Semiconductor Equipment Communication Factory

A real application story in semiconductor equipment manufacturing.

Read more →Industries & Applications

From 5‑axis aerospace parts to semiconductor components and lights‑out pallet pools—see proven workholding approaches that cut setup time and boost repeatability.

Aerospace & Defense

5‑axis parts, exotic alloys, multi‑op repeatability.

Automotive

High throughput, stable cycle time, hydraulic fixtures.

Medical Devices

Small parts, tight tolerances, gentle yet rigid clamping.

Mold & Die

Electrodes, inserts, deep cavities, fast changeovers.

Semiconductor & Electronics

Precision positioning for equipment and communication components.

Lights‑Out Automation

Pallet pools, robotic tending, quick‑change zero‑point setups.

Workholding Selection Checklist

A quick way to pick the right fixture, baseplate, or quick‑change system—before you commit to a setup.

Before you choose, confirm:

-

Machine & access: 3‑axis / 5‑axis / HMC, tool reach, collision envelope.

-

Part mix & changeovers: Batch size, weekly changeover frequency, pallet strategy.

-

Tolerance & repeatability: Datum scheme, probing plan, target repeatability.

-

Material & cutting forces: Aluminum vs. titanium/Inconel, roughing loads, chatter risk.

-

Coolant & chips: Flood vs high‑pressure, sealing, corrosion resistance.

-

Automation readiness: Robot interface, sensors, air/hydraulic supply, M‑code logic.

-

Workpiece protection: Thin walls, surface finish, soft jaws/pads where needed.

Common goals → Typical NextasTech setup

Fast changeovers & pallet pools: Combine Zero‑Point Systems with the Pneumatic Zero‑Point Plate and an Automatic Pallet Changer.

5‑axis access in one setup: Use a Self‑Centering Vise on a Zero‑Point Clamping Plate (or a Dovetail Fixture for maximum tool clearance).

High‑volume stability: Standardize with a Customized Hydraulic Fixture and a dedicated chuck (E‑Series / R‑Series).

Delicate small parts: Choose a Pneumatic Vise for consistent clamping force and repeatable positioning.

Modular prototyping: Start with Rapid Prototyping tooling on a quick‑change base to iterate fast.

Repeatability across machines: Adopt shared reference pallets and zero‑point positioning to move jobs between VMC/HMC cells without re‑indicating.

Need a quick recommendation? Share your drawing, material, machine type, and target tolerance—our engineers will propose a stable, production‑ready setup.

Get a setup recommendationWhy Choose NextasTech?

The competitive advantages that drive your success.

On-Time Delivery

Ensure quick turnaround times with fast, reliable delivery.

High Quality & Precision

Guaranteed repeatability of ±0.002 mm for ultimate accuracy.

CE & ROHS Certified

Unlocks global markets, ensuring compliance and trust worldwide.

Superior Sales Service

Ensures support, builds trust, and guarantees long-term satisfaction.

Our Manufacturing Strength

NextasTech Co. Ltd. was established in 2009, dedicated to industrial workholding solutions for 16 years. NextasTech has its own factory premises covering an area of 43,600 square meters, housing an R&D base, manufacturing workshop, assembly workshop, and quality inspection room. We are equipped with world-class precision machining equipment such as Hardinge (USA) and OKUMA (Japan), as well as grinding machines from Okamoto (Japan) and Moore (USA), providing a strong guarantee for high-quality, batch production.

%20Precision%20Grinding%20Machine.png?updatedAt=1753928260610)

Okamoto(JP) Grinding Machine

5-Axis%20Machining%20Center.png?updatedAt=1753928454556)

Matsuura(JP) 5-Axis Center

%20Vertical%20Machining%20Center.png?updatedAt=1753928454495)

Okuma(JP) Vertical Center

%20Precision%20Lathe.png?updatedAt=1753928454979)

Hardinge(US) Precision Lathe

%204-Axis%20Machining%20Center.png?updatedAt=1753928260973)

Brother(JP) 4-Axis Center

%20Jig%20Grinder.png?updatedAt=1753928454118)

Moore(US) Jig Grinder

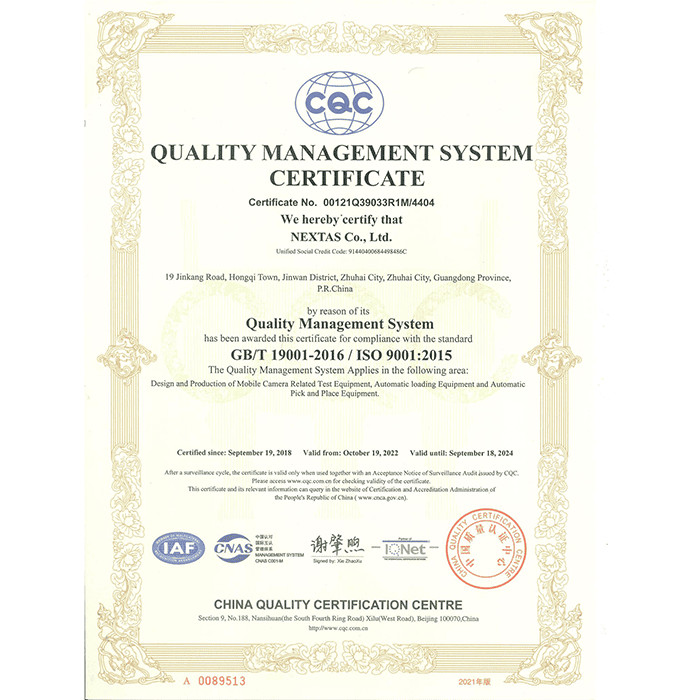

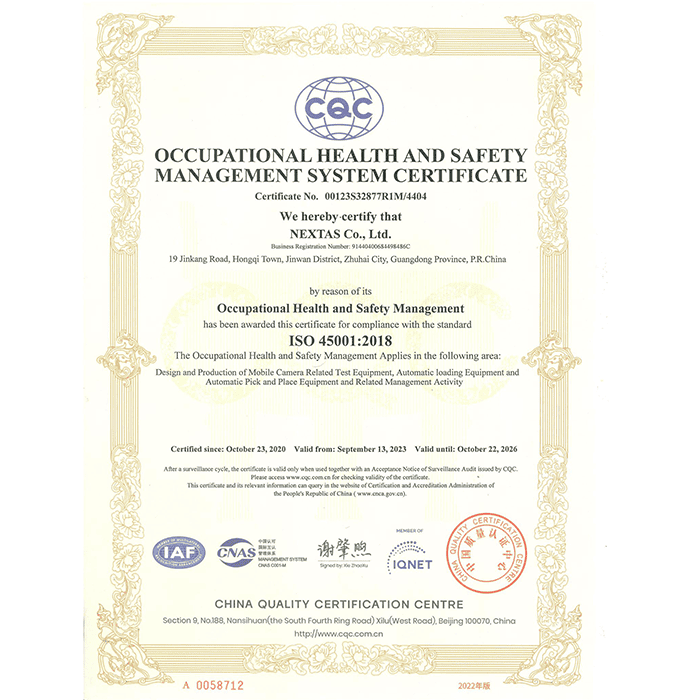

Our Commitment to Unwavering Quality

Validated by internationally recognized certifications, reflecting our systematic approach to quality, safety, and environmental responsibility.

Quality Management

Environmental Management

Occupational Health & Safety

Certificate of Conformity

Our Global Footprint

Exhibition Highlights

Explore our journey through major industry exhibitions worldwide. See our innovations in action and connect with our team on the global stage.

Our Business Philosophy

At NextasTech, our philosophy revolves around three core principles: product quality, competitive pricing, and exceptional service. We rigorously control quality from raw materials to final inspection. Our three-tiered service system—pre-sales, in-sales, and after-sales—ensures we address all customer needs.

ABOUT NextasTech

Founded in 2009, NextasTech focuses on the CNC industry, providing optimal machines and accessories at the best prices for our customers.

About NextasTech

APPLICATIONS

We provide versatile solutions for demanding industries like Aerospace, Automotive, and Medical Devices, engineered to boost precision and throughput.

View Applications

CONTACT NextasTech

Reach out to us for quotes, support, or any inquiries. We are here to help you find the perfect solution for your needs.

Contact NextasTechOur Core Technology

The engineering behind our unmatched precision and speed. Discover the innovation that drives your productivity.

Unrivaled Clamping Force & Rigidity

Our zero-point system utilizes a patented locking mechanism with high-precision tapered pins. This design ensures exceptional rigidity and delivers over 25,000N of clamping force, eliminating micro-vibrations for superior surface finishes.

Micron-Level Repeatability

Achieve workpiece changes in seconds while maintaining ±0.002mm repeatability.

Rapid Actuation

Pneumatic or hydraulic actuation ensures fast, reliable, and consistent locking.

Built for Endurance and Precision

We use only the highest-grade materials. Critical components are crafted from high-hardenability steel and undergo specialized heat treatment processes to achieve exceptional hardness and wear resistance, guaranteeing long-term performance.

Superior Wear Resistance

Ensures sustained accuracy and reliability even under the most demanding production schedules.

Corrosion Protection

Special coatings protect against corrosion from coolants and environmental factors.

Seamless Integration with Robotics

Our systems are engineered for the future of manufacturing. Features like integrated air-blast self-cleaning and sensor feedback ports allow for seamless integration with robotic loading, unloading, and fully automated cells.

Air-Sealed & Self-Cleaning

Prevents debris and coolant from compromising accuracy, ensuring 24/7 reliability.

Integrated Sensor Ports

Provides clamping/unclamping feedback to your automation system for safe operation.

Frequently Asked Questions

What is the repeatability of your zero-point systems?

We guarantee a repeatability of ±0.002 mm. All products are verified on certified CMM equipment before shipment to ensure consistent quality for every part.

What materials are your core components made from and what is their hardness?

Our core components, such as clamping pins and receivers, are crafted from high-hardenability alloy steel. They undergo a proprietary heat treatment process to achieve a surface hardness of HRC 58-62, ensuring exceptional wear resistance and long-term stability.

How does the self-cleaning function work in your automation chucks?

Our automation chucks feature integrated air-blast channels. During the un-clamping sequence, a high-pressure air blast is directed at the mating surfaces (tapered pins and receivers) to clear away chips, coolant, and other debris. This ensures a clean and precise connection for the next pallet, which is critical for maintaining repeatability in automated cells.

Do you offer customized workholding solutions for unique applications?

Absolutely. While we offer a comprehensive standard product line, our engineering team specializes in developing custom solutions. We can design and manufacture bespoke fixtures, pallets, and clamping systems tailored to your specific workpiece geometry, machine specifications, and production goals. Contact us to discuss your project.

For 5-axis machining of thin-walled or delicate parts, what workholding do you recommend?

For delicate or thin-walled components where distortion is a concern, we highly recommend our Dovetail Fixtures. They provide exceptional clamping force with minimal material engagement (e.g., a 3mm dovetail) on the raw stock. This low-profile clamping allows for maximum tool access (5-side machining) while applying clamping forces in a direction that minimizes part deformation, ensuring high precision and stability.

How does your Self-Centering Vise maintain accuracy over time?

Our self-centering vises achieve high precision (centering accuracy of ±0.005mm) through a hardened and precision-ground leadscrew and nut system. More importantly, they feature an adjustable backlash-free nut design. This allows for compensation of any potential wear over years of use, enabling the vise to be recalibrated back to its original high accuracy, ensuring a long and precise service life.

Ready to Supercharge Your Machining?

Contact our experts today for a free consultation and quote.

Consult via WhatsApp