In semiconductor equipment communication manufacturing, micron-level positioning errors can turn into signal instability, scrap, and late deliveries. SAVANT—an established manufacturer of semiconductor communication equipment and core components—needed a way to increase throughput without compromising repeatability across multiple stations.

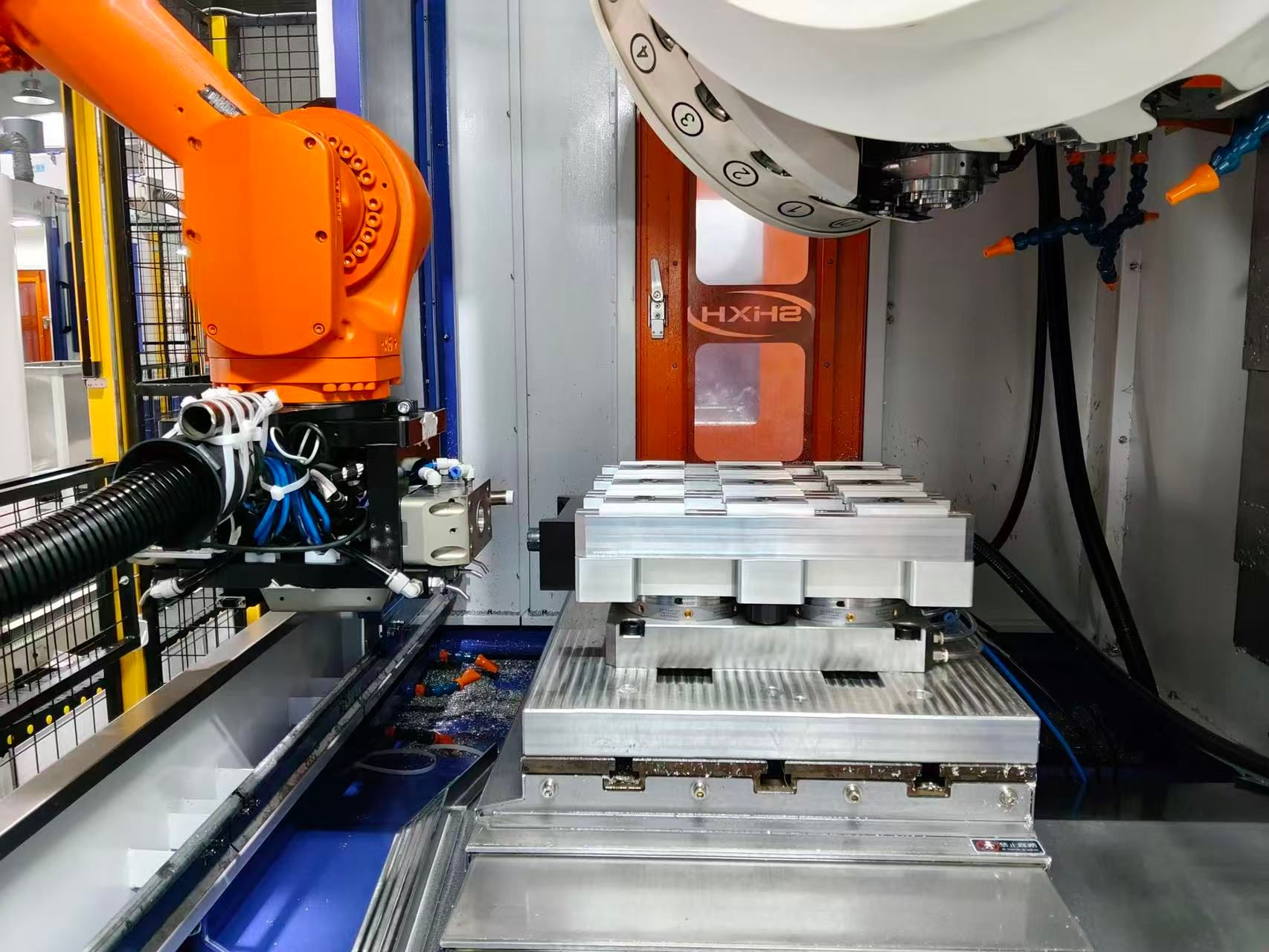

After technical evaluation and benchmarking, SAVANT deployed the NextasTech Zero Point Positioning System and integrated it with its existing NextasTech FMS (Flexible Manufacturing System). The outcome was a faster, more stable, and more connected machining workflow—built for small-batch, high-mix production.

Why semiconductor communication machining needs zero-point accuracy

Semiconductor communication modules and signal transmission components are unforgiving: tolerances are tight, and part-to-part consistency matters as much as absolute accuracy. The “core demands” SAVANT highlighted were:

- Precision & repeatability across machining, inspection, and transfer steps

- Stability under high-speed cutting to avoid micro-vibration and part shift

- Efficiency: rapid changeovers and predictable cycle times

- Automation compatibility so robotics and FMS workflows stay uninterrupted

SAVANT’s bottlenecks before NextasTech

Before adopting the NextasTech solution, SAVANT’s precision machining lines were slowed down by common “legacy” constraints:

- Long manual calibration & clamping — up to 30 minutes per workpiece changeover

- Inconsistent positioning — manual operation led to deviations up to 0.01mm, contributing to a 3–5% defect rate for high-precision parts

- Fragmented process connectivity — isolated stations reduced automation continuity and increased manual intervention

What SAVANT needed was a positioning “backbone” that could anchor every station to the same reference—fast.

How NextasTech solved it: key technical advantages

1) Micron-level repeatability for multi-station consistency

The system delivers repeat positioning accuracy of ≤0.003mm, aligning with NextasTech’s benchmark of ±0.002mm precision. For SAVANT, this meant:

- Stable zero-point reference between 5-axis machining centers and inspection stations

- Less re-calibration during transfers

- Fewer defects linked to positioning drift

2) Fail-safe spring-actuated mechanical self-locking

Clamping force is maintained by powerful springs, with pneumatic pressure (typically 0.5–0.8MPa) used only for unlocking. SAVANT configured modules (e.g., around 18kN for medium-load parts) within a broader range of 4kN–40kN. This “fail-safe” approach keeps workpieces secure even during air interruptions—ideal for high-speed cutting (up to 12,000rpm).

3) Second-scale changeovers (up to ~90% setup-time reduction)

With tool-free rapid clamping and replacement, SAVANT reduced changeover time from 30 minutes to around 30 seconds—a reported 92% reduction. This flexibility is especially valuable for high-mix semiconductor communication orders.

4) Seamless synergy with NextasTech FMS for intelligent flow

The system is designed for automation, with pneumatic control ports, status detection capability, and self-cleaning air channels. At SAVANT, the integrated workflow supports:

- Robotic loading → zero-point positioning → machining → transfer → inspection

- Reduced manual handoffs (lower human-error exposure)

- Real-time clamped/unclamped signals to PLC for safer unmanned shifts

5) Industrial-grade durability for harsh shop conditions

Hardened stainless steel (surface hardness roughly HRC 58–62) with corrosion-resistant coatings helps the system resist coolant and chip exposure. A built-in self-cleaning blast during unlocking helps keep interfaces debris-free, reducing maintenance frequency and helping preserve long-term repeatability.

Measured results after deployment

After full deployment on SAVANT’s semiconductor equipment communication line, reported outcomes included:

- +38% throughput increase for semiconductor communication modules

- Defect rate due to positioning errors reduced from 3.2% to 0.15% (qualification rate > 99.85%)

- -35% order delivery time (cycle time improvement)

- -22% labor cost, supported by automated process integration

Implementation checklist for your shop

If you’re planning a similar upgrade, here’s a practical checklist to keep the rollout smooth:

- Map your stations: machining, inspection, transfer, pallet storage.

- Define load profiles: required clamping force per workpiece family.

- Standardize your reference: align fixtures/pallets around a shared zero-point scheme.

- Plan automation signals: clamped/unclamped detection into PLC/robot logic.

- Validate repeatability: confirm across the full route (machine → inspection → machine).

- Maintain cleanliness: use self-cleaning + routine checks to protect interface precision.

Explore NextasTech Zero Point Systems

Want to evaluate a configuration for your parts? Start here:

- NextasTech Zero Point Systems

- Universal Zero-Point Clamping Plate

- How NextasTech FMS enables intelligent manufacturing

- Talk to our engineering team

Tip: If you’re currently battling long setup times, inconsistent transfer accuracy, or automation bottlenecks, zero-point positioning is often the fastest “multiplier” you can deploy—because it improves every downstream step.