Pneumatic Performance: The Foundation of Automated Reliability

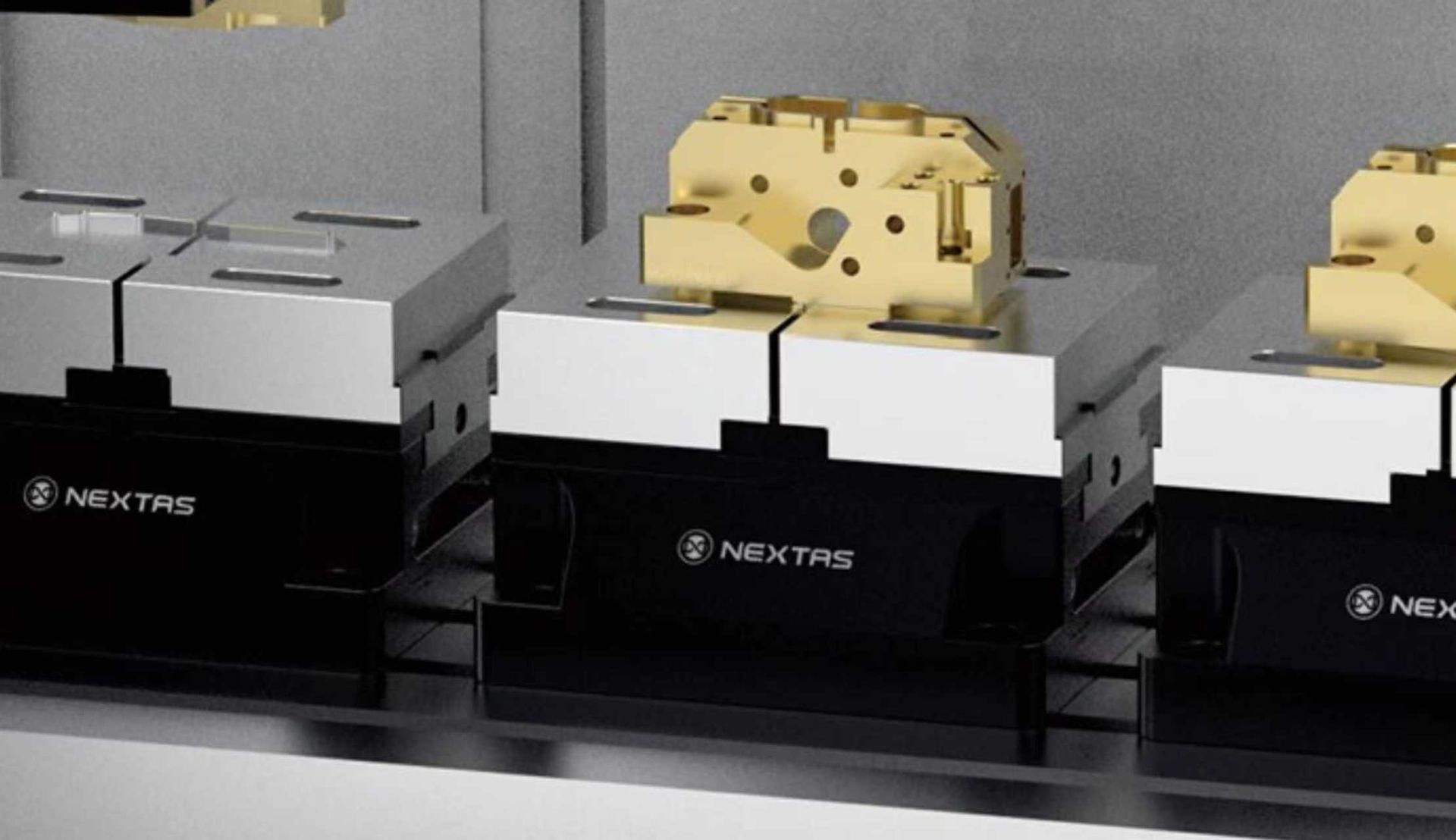

Unlike manual or hydraulic vises, a high‑precision pneumatic vise relies on compressed air for actuation—delivering consistent, repeatable clamping (often within ±0.005 mm) that’s essential for automated workflows. This pneumatic advantage eliminates human variability: no more over‑tightening that damages delicate medical parts, or under‑clamping that risks slippage during aerospace component machining. The air‑driven design also ensures fast response times—clamping and releasing in seconds—laying the groundwork for rapid changeovers. Pneumatic systems generally have long operating lives and require little maintenance.

Machine Program Control: Syncing with Automated Systems

What truly integrates high‑precision pneumatic vises into modern automation is their ability to be controlled via machine tool programs. CNC machines can send real‑time signals to adjust clamping force, activate safety locks or trigger release—all without manual intervention. For example, in a medical part machining line, the vise automatically tweaks pressure when switching from aluminum to titanium workpieces, ensuring optimal grip without compromising part integrity. This programmability turns “set‑it‑and‑forget‑it?into a reality.

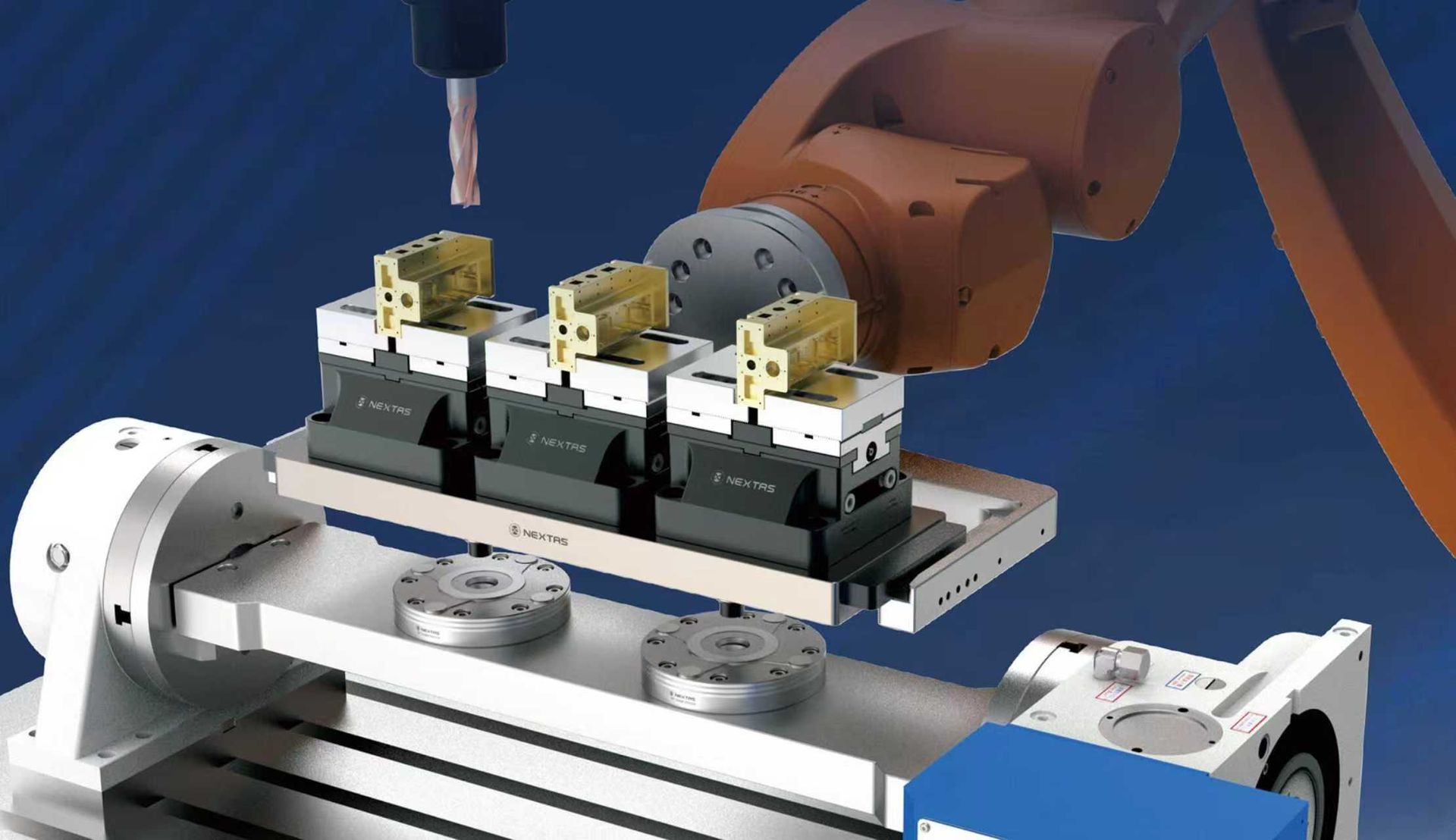

Collaboration with Robotic Arms: Streamlining Load‑and‑Clamp Cycles

The magic of automation happens when tools work in harmony—and high‑precision pneumatic vises pair seamlessly with robotic arms. As the robot executes its gripping and placing motions, the vise’s pneumatic actuation syncs perfectly: the robot positions a workpiece, the vise clamps instantly, and once machining ends, it releases just as the robot returns to load the next part. This coordination cuts changeover time by 80% or more compared to manual setups.

Enabling 24/7 Uninterrupted Operation

For manufacturers chasing maximum uptime, the high‑precision pneumatic vise is a game‑changer. Its durable pneumatic components (resistant to wear and debris) and “fail‑safe locked?design ensure it can run round‑the‑clock. In lights‑out factories—where production of goods is fully automated without requiring human labour—CNC machines can run unattended, keeping lines moving even overnight. Lights‑out manufacturing isn’t science fiction; robot‑built robots at Fanuc run unsupervised for weeks, proving that 24/7 automation is achievable.

Why It Matters for Specialized Industries

In aerospace manufacturing, where parts like turbine blades require micron‑level precision, the vise’s consistent clamping prevents misalignment that would ruin expensive materials. In medical part machining, its gentle‑yet‑secure grip protects fragile components like surgical instruments, avoiding costly scrap. For any automated line, it’s not just a clamping tool—it’s a bridge between precision, speed, and uninterrupted productivity.

Conclusion

As automation evolves, the high‑precision pneumatic vise remains a non‑negotiable component for factories aiming to stay competitive. Its pneumatic performance, machine programmability, and robotic compatibility don’t just boost efficiency ?they redefine what’s possible for 24/7, error‑free manufacturing.